Mount Snow has become the most powerful snowmaker on the East Coast. Thanks to the West Lake Water Project, the Vermont resort has constructed a 120-million-gallon water storage pond, three pump houses and 100 percent fixed snow-guns and new snowmaking pipelines. The $30 million investment has increased the resort’s water storage by six times and will aid in opening the slopes earlier in the season. FREESKIER caught up with Brendan Ryan, longtime snowmaker and VP of special projects at Peak Resorts, about the nuances of snowmaking in West Dover.

What is the single greatest misconception, in your mind, when it comes to the general public’s knowledge of snowmaking?

Most people don’t understand the correlation between output and temperature. In other words, we can’t make snow at 32 degrees unless the relative humidity is below 55. The other side of this, however, is that you can make snow all the way up to about 39 degrees Fahrenheit if the humidity is near zero.

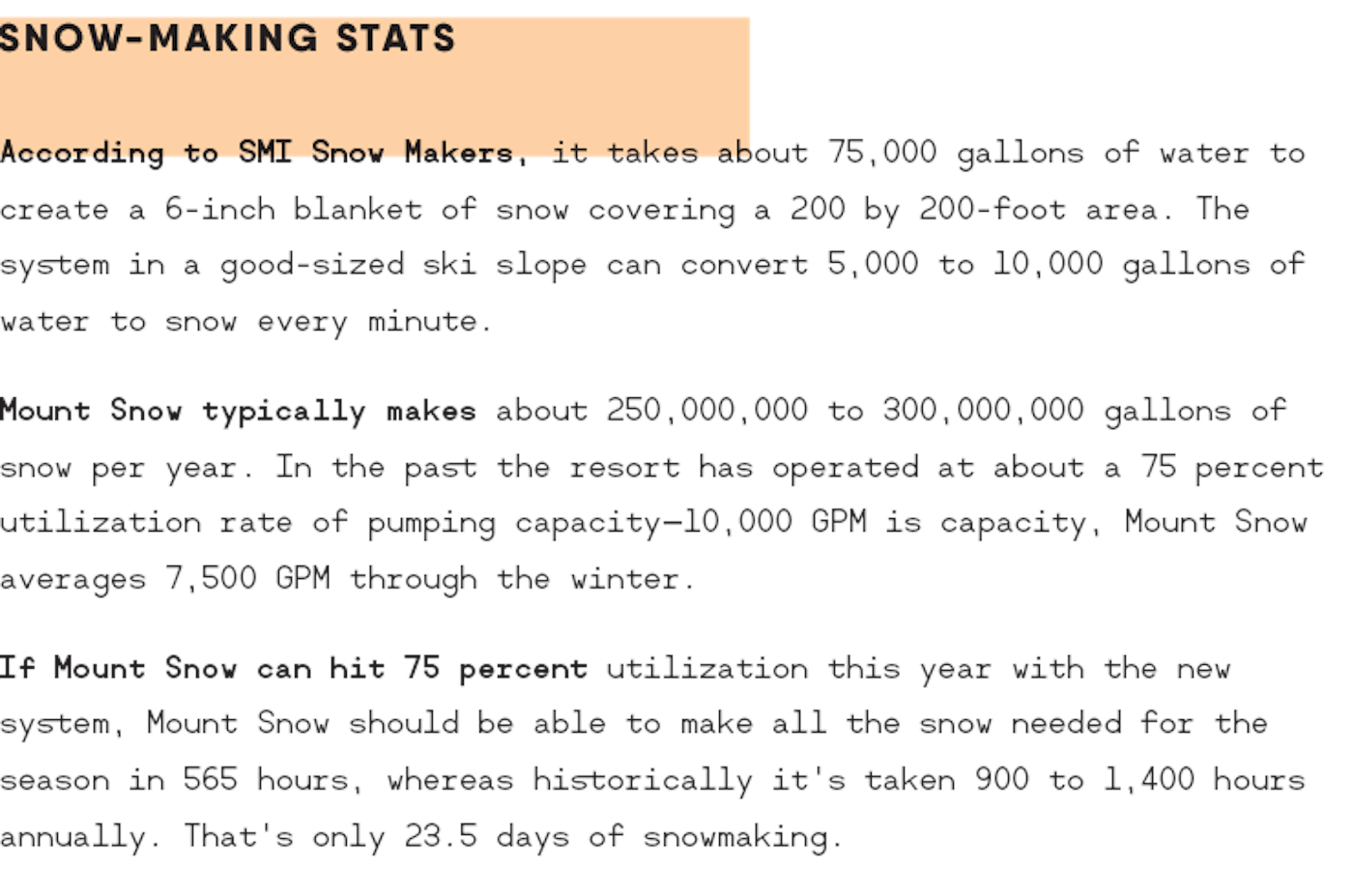

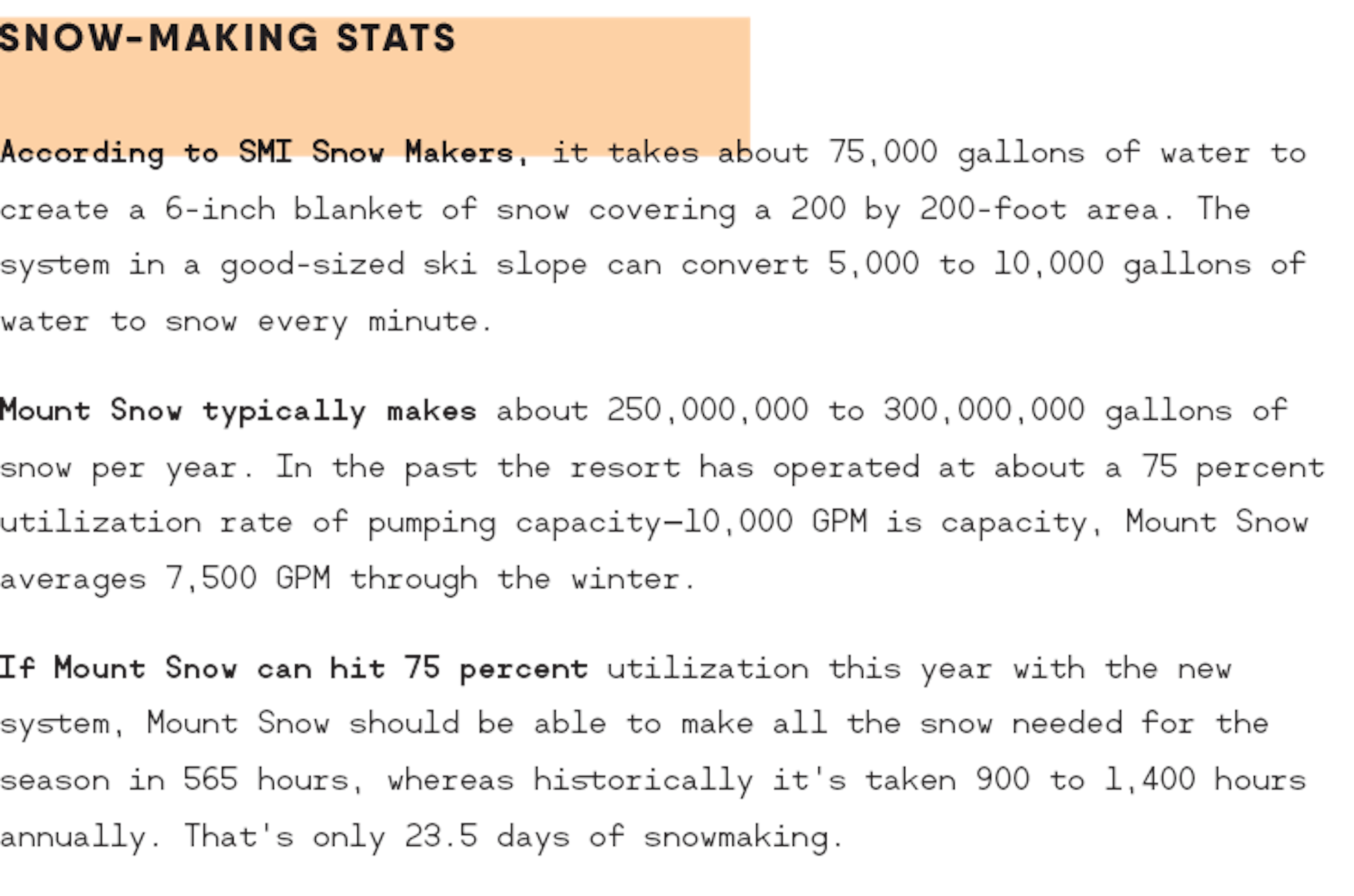

The second part of this is how much snow you can make at different temperatures. I love the example of the SMI Super Polecat. At 400 PSI that gun puts out 25 gallons per minute (GPM). When the temperature gets down to around 15 degrees, that gun puts out 125 GPM—for roughly the same cost to operate. That is a massive difference in production.

Skier: Chris DeJohn | Photo: Mackenzie Hennessey/caption]

Temperature, humidity, “wet bulb temp,” evaporation, surface area, super cooling… Can you provide a brief description of the ideal environment in which to make snow? More often than not, the conditions are not ideal. So, how do you decide when it’s the right time to fire ‘em up?

The physics of snowmaking are pretty wild. Some of the major phenomena that we are working with are expansive cooling, evaporated cooling and convective cooling or heat transfer. The water flows through pipes, which are cold. As the water flows, it becomes colder and closer to freezing. We then cram high-pressure water through small holes at the tip of the gun and onto the slopes.

As water exists in the snow guns it expands and cools. All of our guns now have specific nucleation processes, where we are creating separate, super-cooled small particles that form the center of what we call the “snow-ball” [man-made snow is spherical in shape, unlike natural snowflakes]. These “nuclei” are completely frozen and generally are formed at the center of the gun. We then add bulk water to these particles. The colder it is, the more we can add and the more snow we make.

I think if you asked most snowmakers, they would tell you that 10 to 15 degrees and calm is pretty ideal. You’re at about max production and don’t have to worry about scary things happening when it gets closer to zero.

What are typical working hours for a snowmaker? How many snowmakers work at a place like Mount Snow?

With the new $30 million upgrade, Mount Snow will have 100-percent fixed equipment and will be 100-percent low energy. With this, we are able to flow 11,800 GPM of water, overall, with roughly 2,000 GPM per top-to-bottom trail. This means that we can be making snow on about six runs at a time. From there, each trail has two snowmakers working together, and a supervisor for every two or three trails. Plus the control room and a general manager… call it 18 staffers per shift.

Power consumption to run the guns is a drain economically and environmentally. Some people might regard it as a necessary evil — an integral part of running a profitable business and providing a satisfactory skiing experience. Do you think of it in the same way?

The Mount Snow Operations team takes a tremendous amount of pride in the product that they produce. Every ski resort produces a product, which is a skiable surface accessible by lifts and surrounded by amenities. Some resorts have to make nearly all of their snow, while others have to spend money on blowing up snow for avalanche control. But no matter what side of the spectrum you are on, you get the same end result: an accessible, skiable surface.

I believe that all resorts have a responsibility to produce their product for the lowest possible cost while staying as environmentally conscious as possible. There are few better places that you can make snow and achieve both ideals than Mount Snow.

Since 2011, Mount Snow has reduced its annual energy consumption by over 30 percent. We expect to continue that trend this year with the installation of 220 additional state-of-the-art snow guns, bringing our fleet of 917 guns to 100 percent low energy technology.

Many snow-makers describe the job as a challenging marriage of science and art—the basic elements are precise weather measurements and expensive machinery, but you need instinct, improvisation and creativity to get it exactly right. Can you describe any examples of a time when someone really stood out in your mind, creating masterpieces that left the rest of the team stunned?

Randy Barrows, the snowmaking manager at Mount Snow, is the Michelangelo of snowmaking under the Peak Resorts umbrella. Understanding the broad picture of delivering the best possible product, as quickly as you can, at the right price is the ultimate art in my opinion.

If it’s Christmas Eve and you need to get a key trail open that will ski well, but also handle the abuse of a holiday week, Randy Barrows is your guy. He’ll make the wet base-building snow while understanding the time it takes to put a layer of sweet, dry snow on top that will ski well in the morning. And he’ll do it without needing to groom it all.