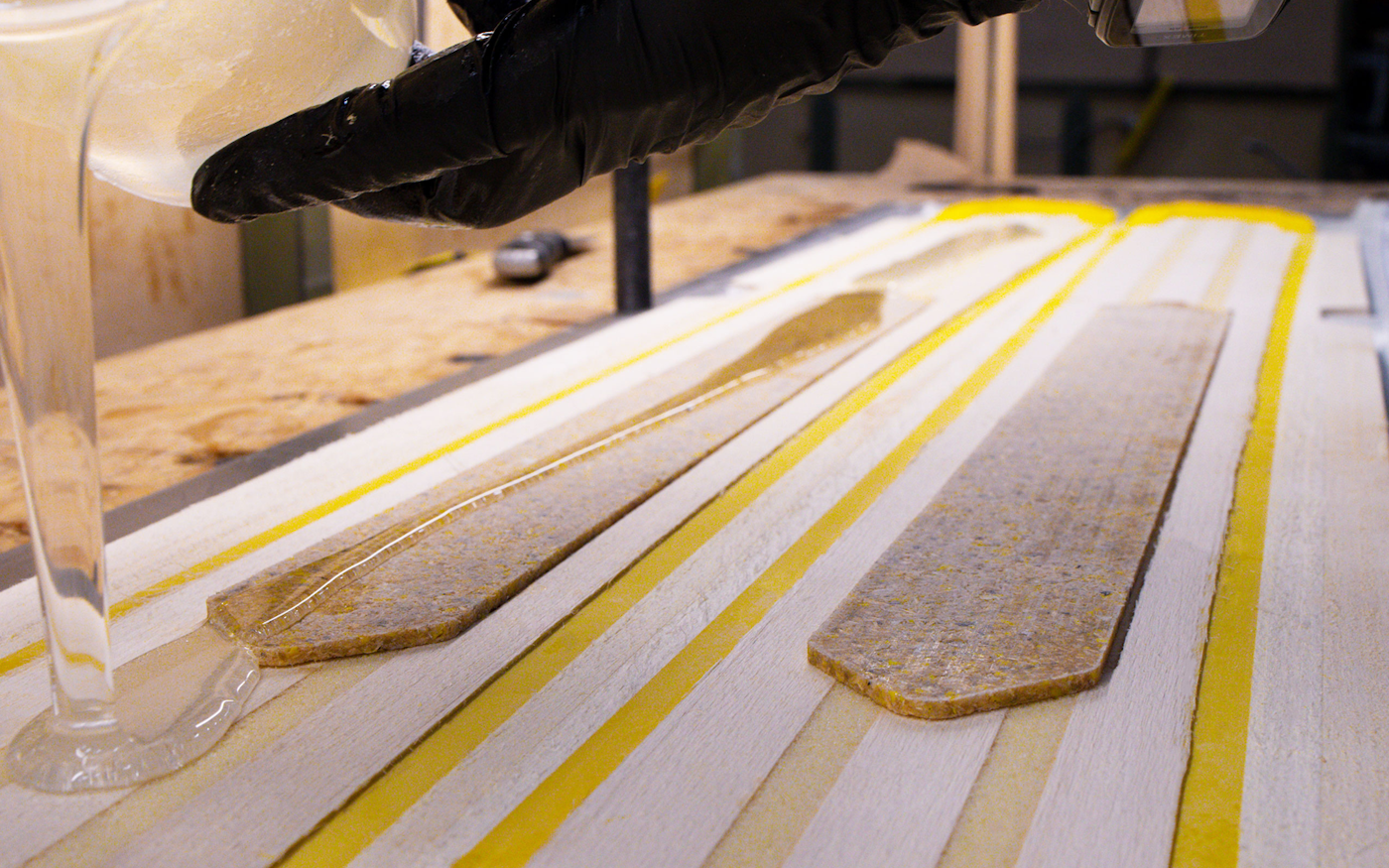

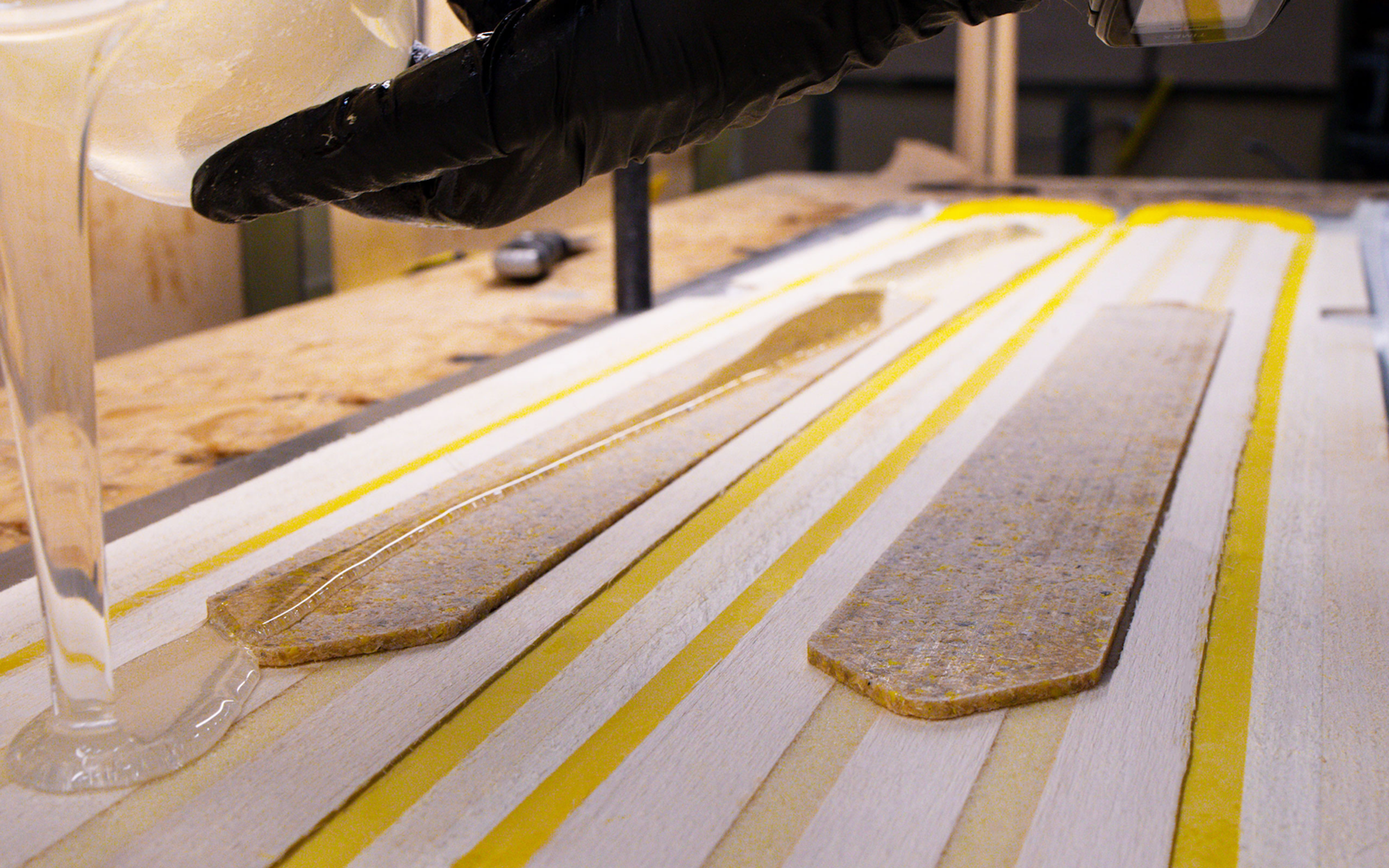

Breaking down the old and making it new. WNDR Alpine’s SpiralMade recycled materials program brings life to the scraps of ski construction. Looking to its own by-products, the Utah-based brand is finding new ways to limit the side-effects of gear manufacturing by taking the excess material, grinding it up into a pulp, pressing it into molds and repurposing it in the construction of new skis and splitboards as a binding-retention plate coined SpiralPlate.

So, how does it work? WNDR Alpine’s SpiralMade materials are derived from their own facility’s reclaimed production waste. Instead of going straight to the landfill, SpiralPlate binding inserts are incorporated into WNDR Alpine’s all-new Intention 108 to give the ski better binding retention strength. For 2023, SpiralMade joins WNDR Alpine’s stability enhancing, algae-derived materials across the brand’s lineup and continues to prove the brand as a leader in developing creative means of reducing the impact the ski world has on the environment.

Photo: Pep Fujas

“It’s incredibly valuable to make one’s own materials and products more easily recyclable,” said Daniel Malmrose, WNDR Alpine’s VP of Product Innovation. “It’s a separate challenge to put one’s own recycled outputs directly into a product in a way that improves the product. Using recycled materials to reach a tangible performance benefit is imperative if we’re to make recycling more viable in the snowsports industry.”

“We embraced the concept of ‘spiral fabrication’ as a play on circularity, acknowledging that while not every material can be re-created in an infinite cycle, we have a very real ability to reconstitute waste material into a new form that’s still valuable,” said Pep Fujas, professional skier and WNDR Alpine’s VP of Marketing and Product Development. “Now that the concept has been proven, we’re excited to bring SpiralMade to backcountry athletes this season.”

Skier: Pep Fujas // Photo: Adam Clark