The inserts in your touring boots, often overlooked but of extreme importance, were most likely made by this company

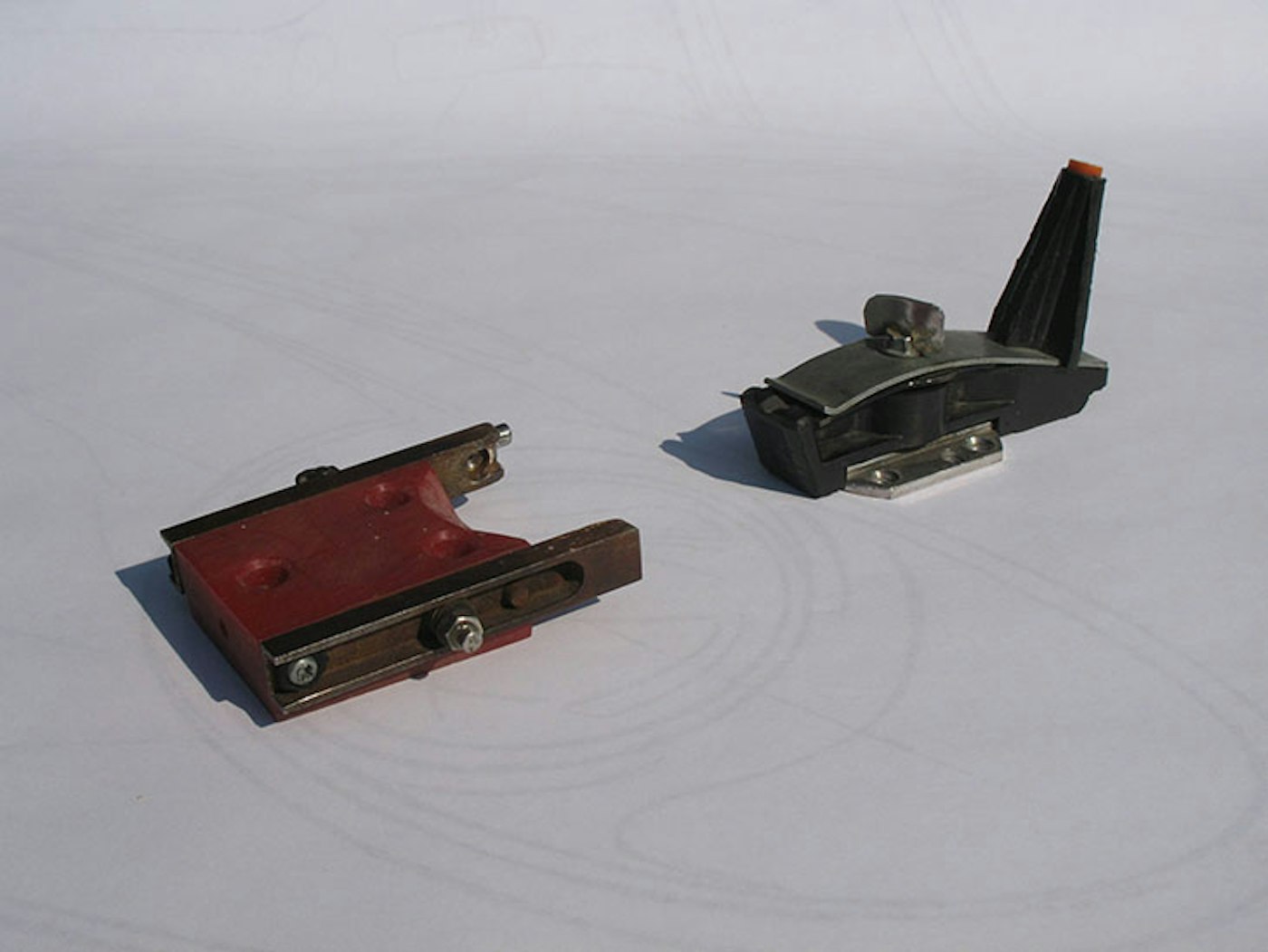

By now, we can assume that the majority of you skiers out there are familiar—either by way of hands-on experience or in passing on the slopes—with the pin binding. If you’re still unsure, the pin binding is a frameless design first engineered by Dynafit’s Fritzl Barthel in the 1980s that utilizes two metal pins in the toe that clamp into corresponding lateral holes on the ski boot toe. The build’s heel piece also relies on pins to hold the back of the boot in place. The “Low Tech” binding, as it’s called, allows for more efficient ski touring because it’s lightweight and provides a smoother pivot point for moving uphill.

Today, approximately 70 percent of alpine touring bindings sold on the market are of the Low Tech variety. Of course, those bindings need to pair with a boot featuring the corresponding inserts in its toe and heel. That intimate connection between boot inserts and binding is more important than people realize, as it must be able to stand up to extreme torque when descending and ensure optimal power transfer from boot to ski.

“It perhaps appears trivial—two holes and two pins on the toe piece and gaps with the coordinating counter piece at the heel—but that is precisely the crux,” says Matthieu Fritsh, product manager of bindings for Dynafit. “The inserts are the connection between the boot and the binding and must be able to withstand an enormous amount, as well as transfer the power of the skier to the ski. In normal cases, when climbing or descending, forces of up to 200 kilograms are transmitted to the inserts, while peak loads could even reach 380 kilograms.”

While countless boot manufacturers rely on these inserts in touring boot construction, there’s one brand that’s supplying the vast majority of them; the company behind the original Low Tech binding system, Dynafit. In fact, 90 percent of boot companies utilize Dynafit-certified inserts in their touring lines.

Dynafit’s thirty-plus years of experience building Low Tech bindings has translated to trust from other manufacturers that understand a high quality and reliable product is a guarantee with the Italian company. The expertise over the product comes with the understanding that the boot inserts and binding pins are all part of the same system.

“It is essential to recognize that the inserts are an external part of the binding… the decisive factors behind the reliability and quality of inserts is the interaction of boot and binding and that they release at the right moment in case of a fall,” Fritsch says.

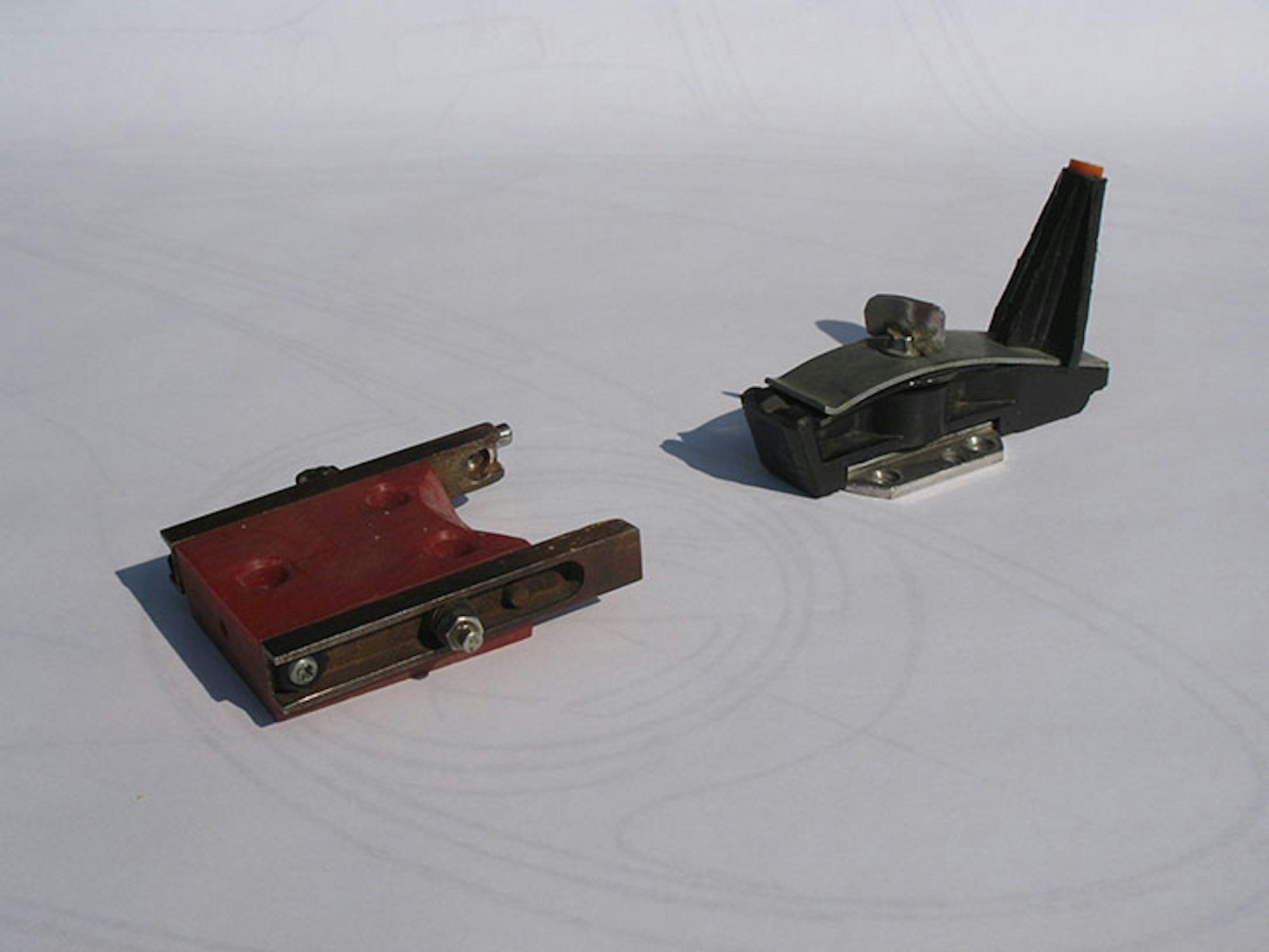

Dynafit’s manufacturing procedure is called the “lost wax process,” where a wax mold is filled with molten metal, heated to about 1,000 degrees Celsius and coated with zinc-based ceramic material that reduces friction. After it’s been cooked and cooled, the molds are vibrated to break off the ceramic material and reveal the final insert. In reality, the whole process is much more complex than that, and Dynafit has mastered the method.

With over thirty years of production comes obvious product evolution. Dynafit has developed three generations of tech inserts, with its standard insert being relied upon by the majority of boot brands for its safety compliance with all touring boot types. The Quick Step-In Insert, developed in 2007, utilized a vertical groove to allow for easier step-in to the binding. The second insert iteration is only used by Dynafit and its Original Equipment Manufacturer (OEM) partner Scarpa. The newest product is the TÜV-certified Master Step Insert, which has even longer vertical entry grooves and wrap-around design for no-think entry, and is twice as strong as previous inserts.

Because it’s the vocal point of the touring binding, the pivot point, the insert system is one of the most important components to keep in mind when purchasing a pair of Low Tech bindings or touring boots. Boots built with Dynafit-certified inserts are marked via a bright orange seal affixed to the boot’s toe inserts, making it easy to identify the standard in tech binding components.

If you, like 90 percent of ski boot manufacturers, covet a strong, quality build and intuitive touring boot to tech binding connection, consider the orange seal when upgrading your gear closet this fall. Click here to learn more about Dynafit.

![[GIVEAWAY] Win a Legendary Ski Trip with Icelantic's Road to the Rocks](https://www.datocms-assets.com/163516/1765233064-r2r26_freeskier_leaderboard1.jpg?auto=format&w=400&h=300&fit=crop&crop=faces,entropy)

![[GIVEAWAY] Win a Head-to-Toe Ski Setup from IFSA](https://www.datocms-assets.com/163516/1765920344-ifsa.jpg?auto=format&w=400&h=300&fit=crop&crop=faces,entropy)