All Images: Courtesy of WNDR

Salt Lake City-based WNDR Alpine has been an industry disrupter since 2019. Founded by Matt Sterbenz and championed by Pep Fujas, you might know WNDR Alpine for pioneering new methods of building skis. Specifically, they have become well known for using oils derived from microalgae grown in their labs instead of the traditional source: petroleum.

Last year, WNDR turned their attention to clothing, to see how they could help replace petroleum-based finishes with algae. They call it biobased performance wear, and it has the potential to change the outdoor industry, and the world, for the better.

FREESKIER reached out to WNDR’s Brand Development Director, Xan Marshland, about what this new term means. “Biobased performance wear is fundamentally about relying on renewable resources,” Marshland told us. “Specifically, [it involves] a biologically derived source of oil, to be competitive or outperform petroleum-based resources.”

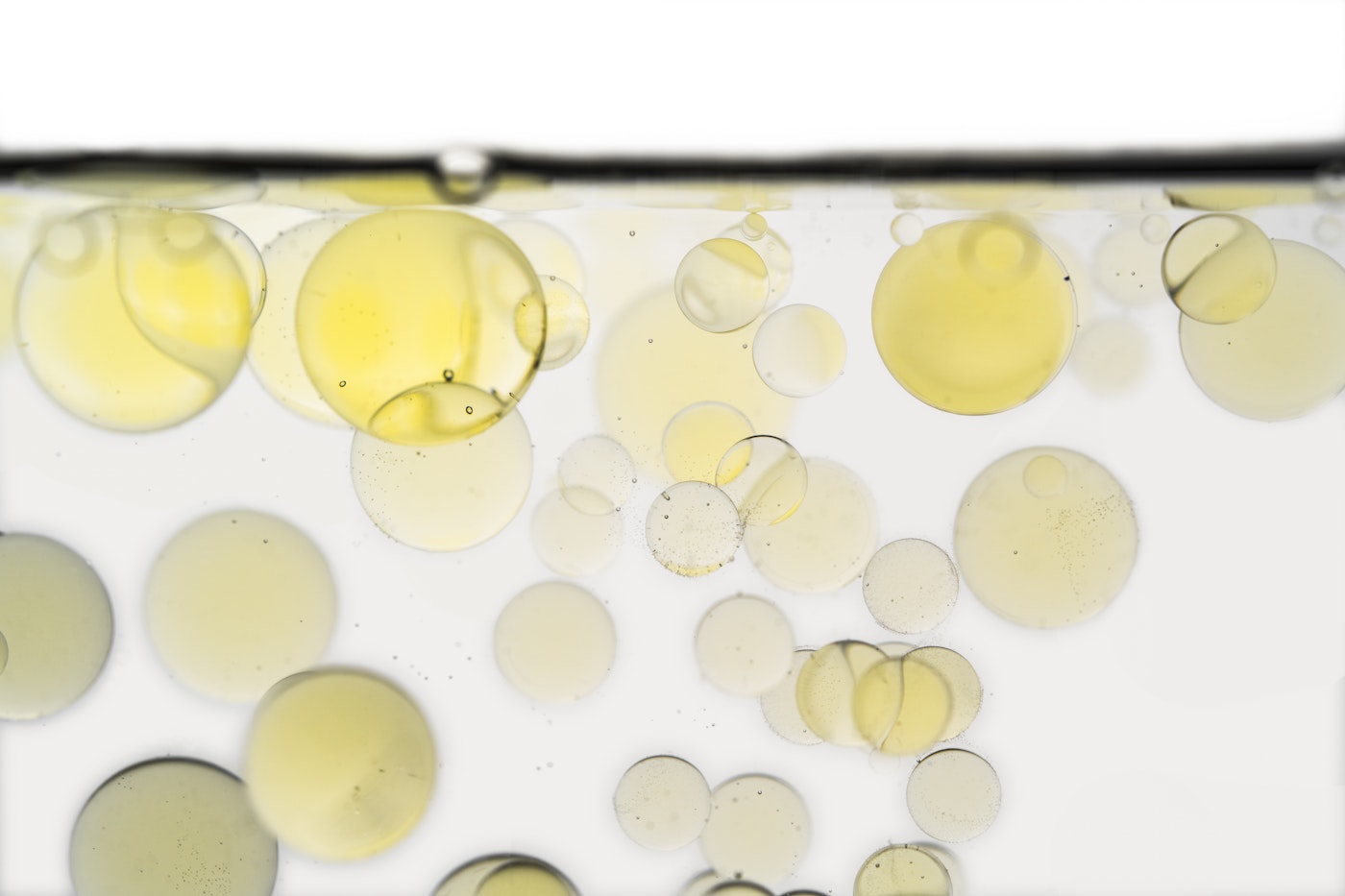

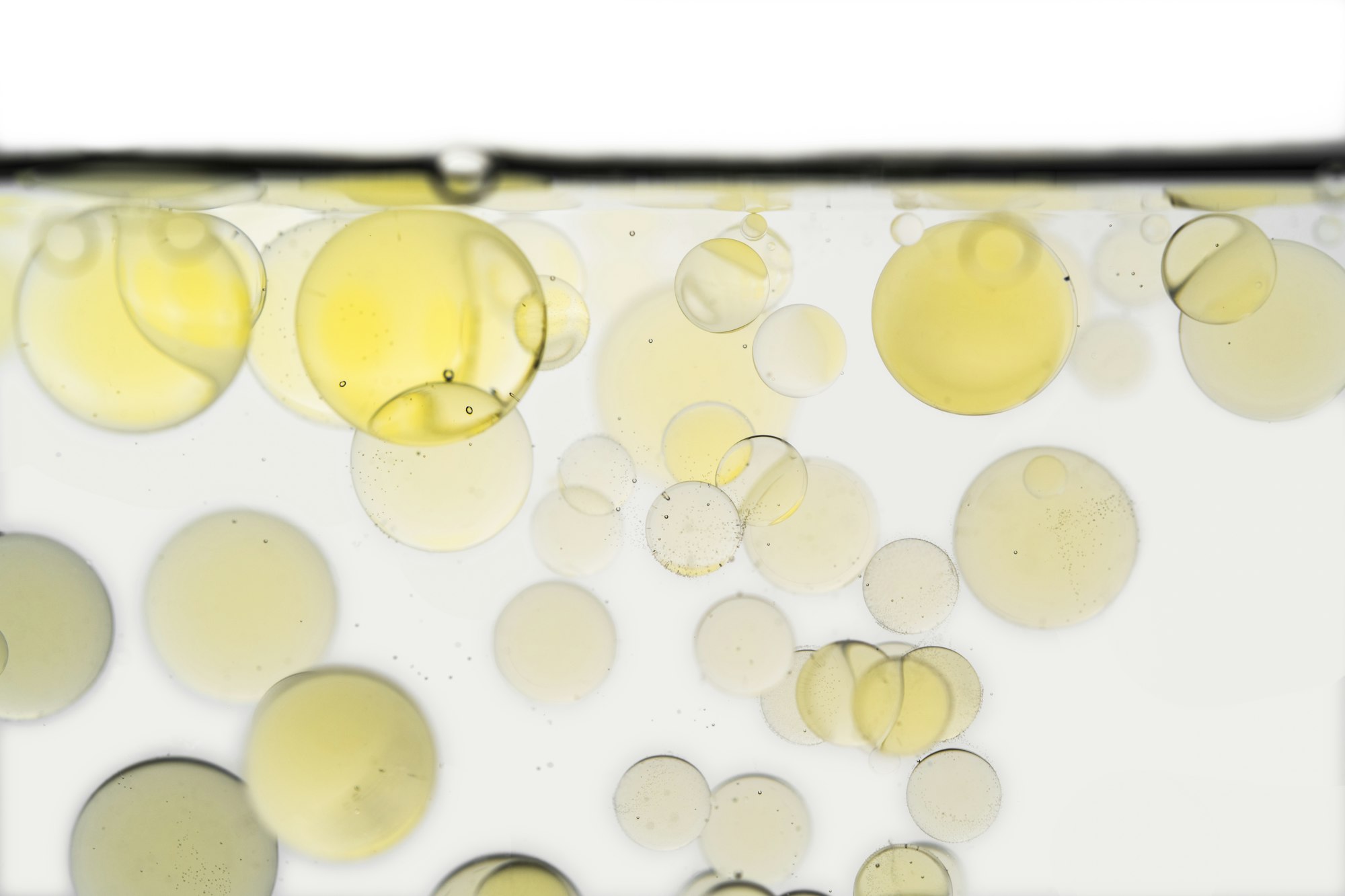

Microalgae oil under the lens. The future is now.

Historically, many clothing finishes have been petroleum-based. Finishes refer to any process that changes the fabric or yarn after manufacturing. These well-known treatments and products and, often used in every big-ticket item on the market, involve an energy-intensive manufacturing process. While these finishes function well, their creation is undoubtedly environmentally taxing.

And it’s not just finishes that utilize petroleum in their creation. Nylon, spandex and polyester, three very popular synthetic fabrics that you’re likely familiar with, (or even wearing right now,) are all petroleum-based. Over 346 million barrels of oil are used in the fashion industry every year, according to a study by the Nordic Fashion Association. The well-documented relationship between fashion and fossil fuels begs the question; why isn’t there an alternative? As crude oil production continues to be a hotbed for political and economic tensions, a better-performing substitute would certainly be appealing to a multitude of industries.

Marshland says these reasons, among others were big influences behind WNDR’s drive to apply their algae-based oil to the world of clothing. They partnered with Swiss green chemistry company Beyond Surface Technologies, the lab responsible for providing textile finishes to a wide variety of brands including Patagonia, The North Face, Tommy Hilfiger and Adidas, to create something new using WNDR’s microalgae oil and BST’s knowledge of wicking finishes.

Together, the team crafted miDori® bioWick, a breathable, hydrophilic moisture-wicking finish. It consists of 100% biobased carbon content and features state-of-the-art performance and durability, even outpacing the competition with up to 10% faster wicking ability on some fabrics. Never before has a biobased, renewable finish been able to functionally compete with and outperform petroleum.

Best of all, it has an 80% lower carbon footprint than a conventional wicking finish. That’s a staggering reduction. The miDori® bioWick and its subsequent benefits are the bread and butter behind WNDR’s new Phase Series of apparel, which include the Durinal Tech Hoodie and the Women’s and Men’s Stasis Longsleeves.

The Stasis Longsleeve, with anti-odor and moisture-wicking properties, is a perfect daily driver when on the road.

Carbon footprint is the most relevant metric to look at after performance, according to Marshland. “If it doesn’t work, nobody will buy it. So that’s priority number one. Then the goal becomes doing it in line with your key metrics. For us, that’s looking at the carbon footprint,” he told FREESKIER. “We compared our bioWick to a normal wicking finish using cradle-to-gate [lifecycle] analysis, which, for a standard finish, includes extracting oil, refining it into petroleum, forming that into a wicking finish and then incorporating that into apparel. For us, the comparable process is growing microalgae, extracting oil out of that, formulating the wicking finish and putting that into the apparel. If you compare the two processes apples to apples, it’s an 80% reduction in carbon footprint, which we’re very proud of.”

The miDori® bioWick, this resulting product that features such outstanding characteristics, could potentially be adopted by other companies; massive companies, ones with much more market share than WNDR. Remember, Beyond Surface Technologies applies finishes for global apparel companies like TNF. They are now equipped to supply this bioWick to their clients around the world. If proven a viable long-term substitute, this could be a paradigm-shifting solution.

“Biomanufacturing is real and it delivers,” claimed Beyond Surface Technologies CEO Matthias Foessel. “By using the very same microalgae oil used to formulate the materials going into WNDR Alpine’s skis and boards, we now have available a 100% petroleum-free wicking finish in the Phase Series apparel – with no sacrifice to performance.”

Of course, a key part of this comes back to the idea of functionality. Is it comfortable, and does it work well? So far, the answer to those questions is a resounding yes. WNDR turned to their team of talented athletes and ambassadors to put this new Phase Series through the wringer this winter, making sure it was warm, breathable and practical when in strenuous conditions. Marshland says that the feedback they got helped them create their vision of a perfect product.

He exclaimed that, “the [miDori® bioWick] actually softens a fabric while maintaining durability and increasing evaporation. Thanks to our athletes, we refined the fit and, when combined with the bioWick, produced this apparel line that just feels good! All science aside, it disperses moisture, keeps you dry, cools or warms depending on your surroundings and is excellent as a layer on your skin. I trusted it every day in the mountains this spring.”

Friend of WNDR Kyle Toohey testing a prototype Diurnal Tech Hoodie this winter.

WNDR’s new miDori® bioWick is making waves, from the peaks to the streets.

WNDR Alpine is trying to make a positive change, and so far they’ve shown to be doing so in a real, practical manner. They’re not just wishing for it, they’re creating it. Like others, they have realized that sustainability is not a choice; it has become a necessity. Current trends suggest that by 2090, a majority of ski areas across the continental United States will not be able to operate due to a shrinking winter season.

Aside from the loss of winter recreation, this will come with tremendous humanitarian burdens, as decreased snowfall will inevitably lead to water struggles. After all, between 60% and 70% of water supplies in the Western U.S. come from snowmelt, according to the United States Department of Agriculture. If this discussion was only about having fun in the mountains or losing money, that would be great. But unfortunately, we are engaged in a several-century-long battle for our most precious resource.

As an industry and as a society, we need to find ways to make our habits, both commercial and recreational, more sustainable. This means finding different solutions across the board that use resources which can perform up to par, be quickly reproduced to meet demand and mitigate environmental harm. This is a daunting task, but the good news is that it opens the door for companies to be innovative, advantageous and profitable all in the same breath. WNDR is an example of exactly that, and while the test of time has yet to truly show results, we’re witnessing a very promising start. Create a good product for passionate customers, reduce environmental harm and make money; it’s a pretty superb formula.

![[FIRST LOOK] New 2027 Gear from Dynastar Skis and Lange Boots](https://www.datocms-assets.com/163516/1771020784-gabriel_rovick_freeskiergearlab2024-f4dstudio-05595.jpg?w=200&h=200&fit=crop)