WORDS • DEREK TAYLOR

Above: Matt Sterbenz and Checkerspot CEO Charles Dimmler are all smiles at the cutting edge of materials innovation at Checkerspot HQ in Berkeley, California.

Shortly after becoming General Manager for Snowsports for Checkerspot, Matt Sterbenz sent a survey to his list of ski industry contacts. It included questions about the best recent advances in ski and snowboard technology but also asked how much the environment factors into gear decisions. Sterbenz calls the questionnaire a “gut check,” an affirmation of his choice to leave 4FRNT, the ski company he founded and ran for more than a decade and a half, to work for a biotech company intent on reinventing the materials used to make the gear we rely on.

“The unanimous response of those I asked about sustainability in skiing was that we’re all ostriches,” Sterbenz says. “We all have our heads in the sand. We’ll carpool to the trailhead, we’ll pack out of the backcountry, we’ll try to minimize our impact as much as we can, but the high performing demands we have on our equipment cannot be compromised.”

Currently, that includes using wood cut from forests, petroleum-based plastics and resins and fiberglass and carbon fiber that are toxic to make and dispose of. “The stuff we’re making these skis out of, it’s a little volatile,” Sterbenz says. “It’s not always focused on renewable resources. The visibility consumers have to the toxicity of those materials is very limited as well.”

Checkerspot is named for the endangered Checkerspot Butterfly and plays off the Butterfly Effect—the theory that small changes can have a large impact. The hope is that by changing something small—in this case, the molecules that make up the materials used in outdoor gear—the company will trigger a massive change across the industry, both in sustainability and performance. In turn, Checkerspot uses algae to create oils which become thermoplastics and thermosets. By feeding various strains of algae different sugars, scientists are able to essentially brew in different properties—strength, elasticity, etc. Because they are working on a molecular level, they can reverse engineer these materials for their exact use.

“High-density composites can be used in combination with other materials for ski cores,” says Sterbenz. “Additionally, we can use our technology platform to create tip spacers, side walls, all the way down to the resin systems used to mold skis. But the opportunity is, what is it that we can do with this material that doesn’t necessarily replace other materials, but betters the functionality of the current materials being used?”

This algae-based technology has existed for industrial and military applications for years now, but Checkerspot is specifically targeting outdoor sports—surf and snow, to start. The company’s founders—outdoor enthusiasts in addition to being scientists—see opportunity in an industry where environmental stewardship and sport often go hand-in-hand. In other words, there’s a widespread desire among consumers, retailers and manufacturers to finally be able to pull our heads out of the sand.

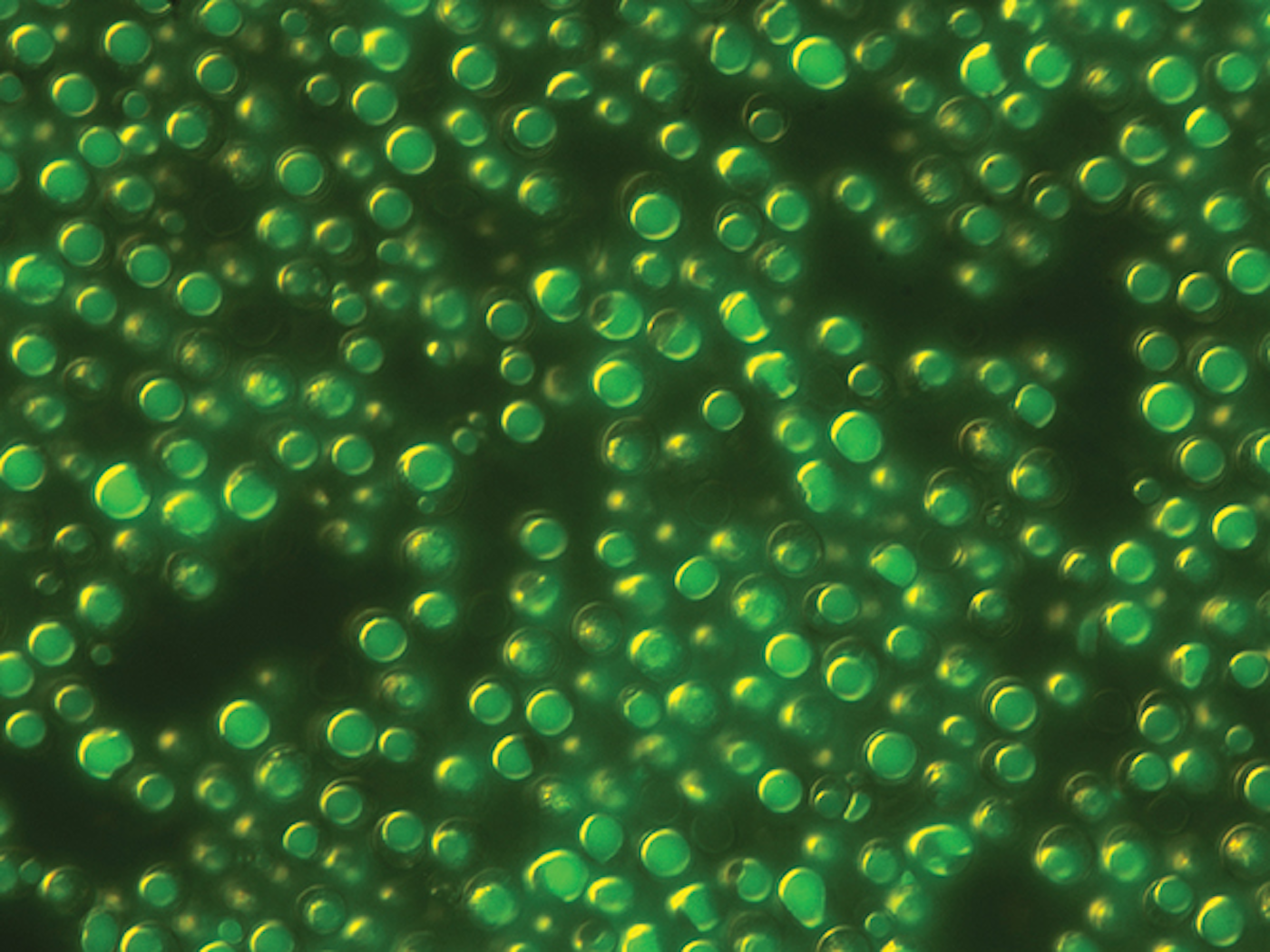

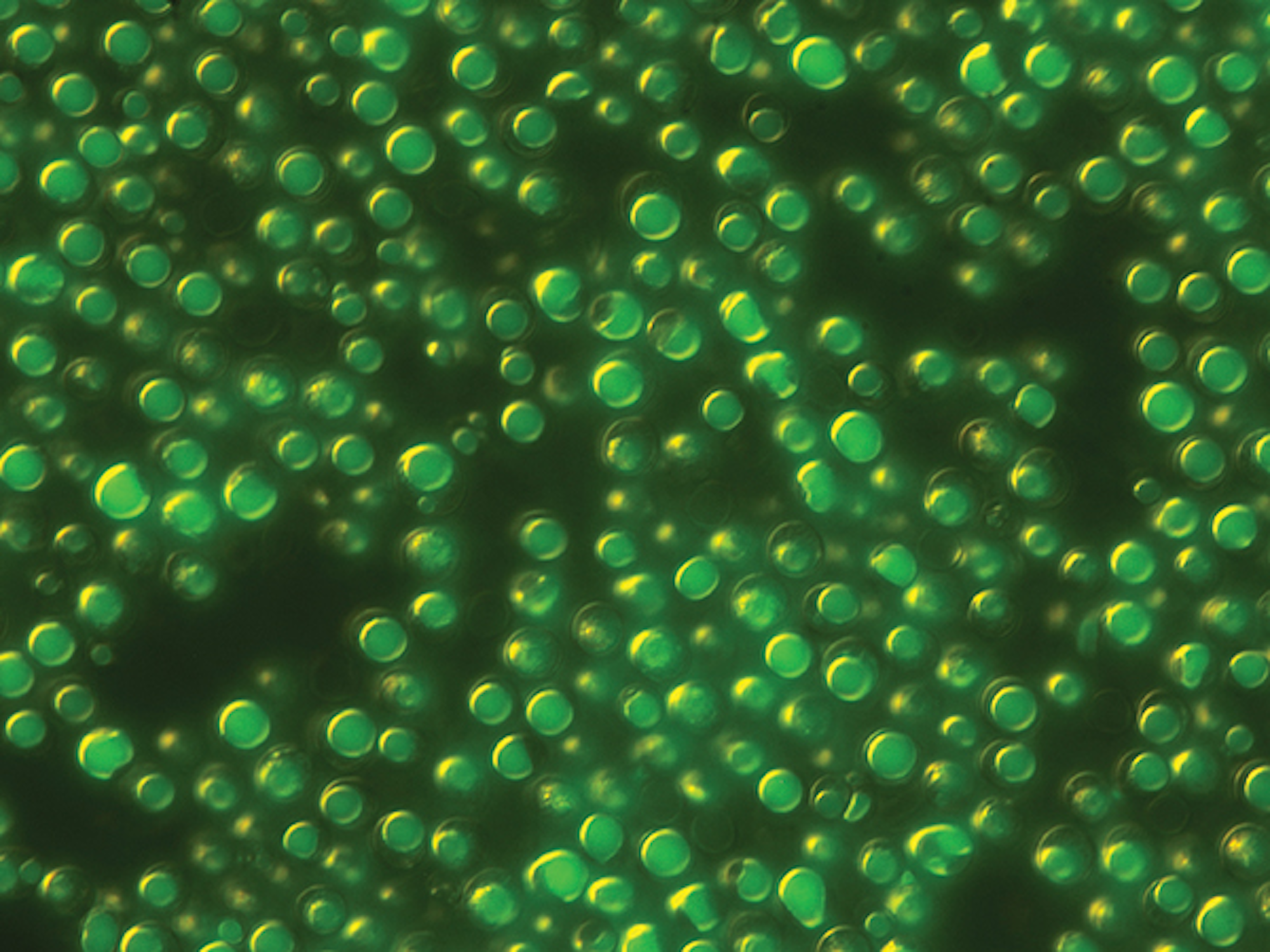

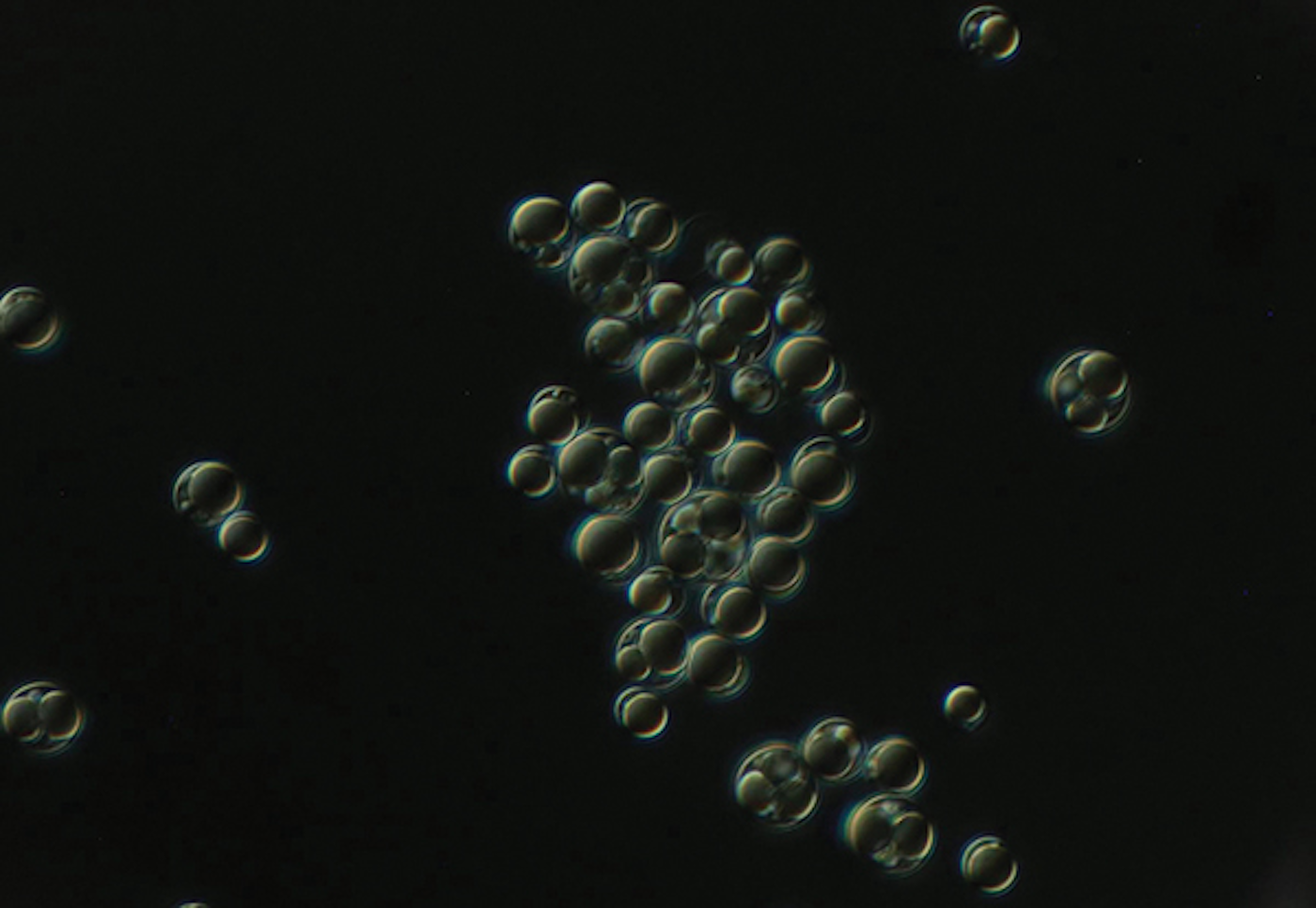

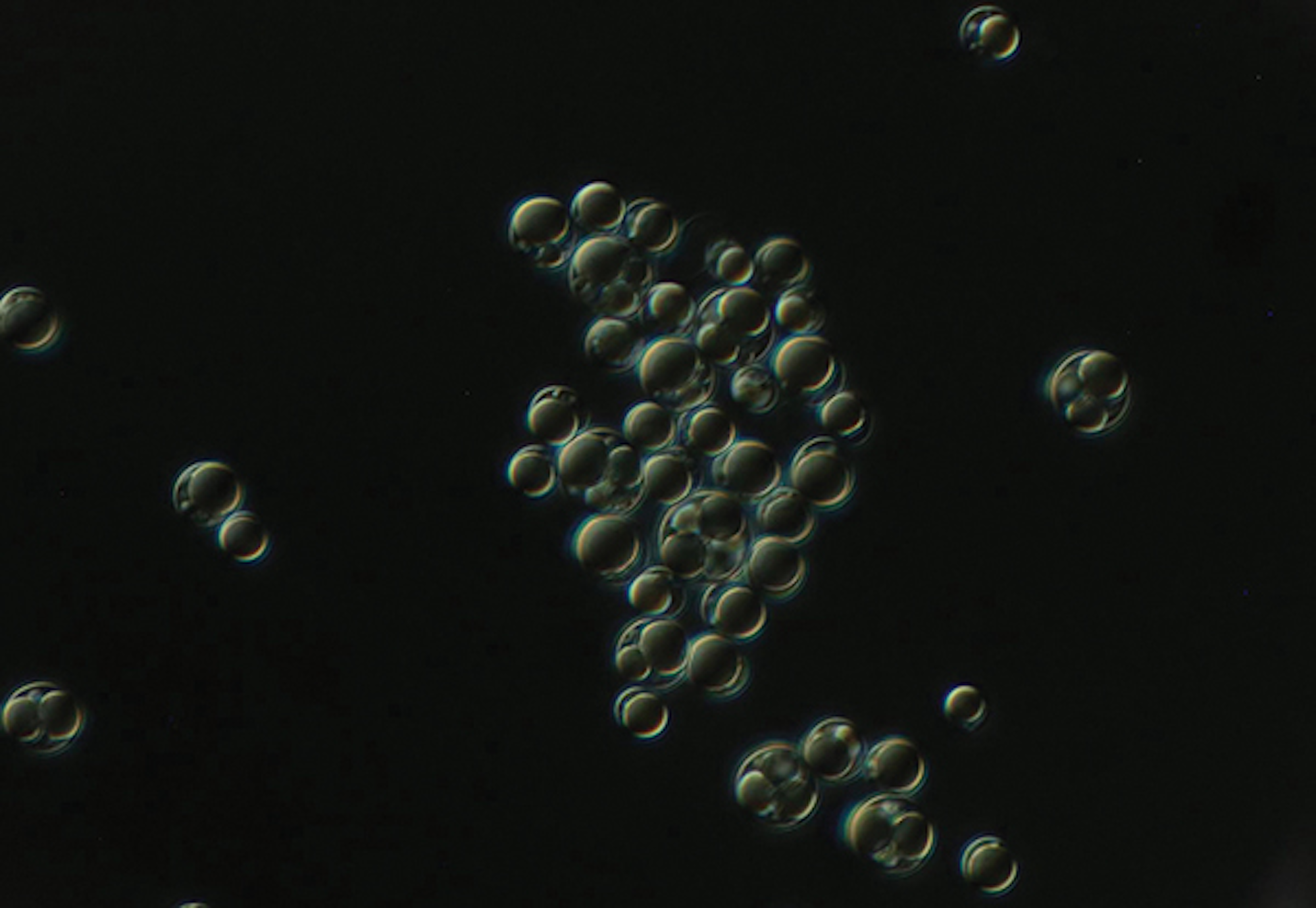

Spherically-shaped micro-algae cells grown in the dark in stainless steel fermentation tanks are filled with oil. This makes them look like tiny spheres within spheres. These unique strains of micro-algae produce the different pristine oils and fatty acids that Checkerspot uses as building blocks for entirely new classes of performance materials.

A bright field image shows the accumulation of large oil droplets forming within individual micro-algae cells. From an evolutionary perspective, algae evolved to produce oil as a matter of survival. Checkerspot takes advantage of this by growing its algae in fermentation (like yeast to make beer) and feeding it sugar; the algae metabolizes it in days and accumulates large amounts of oil within its cells.

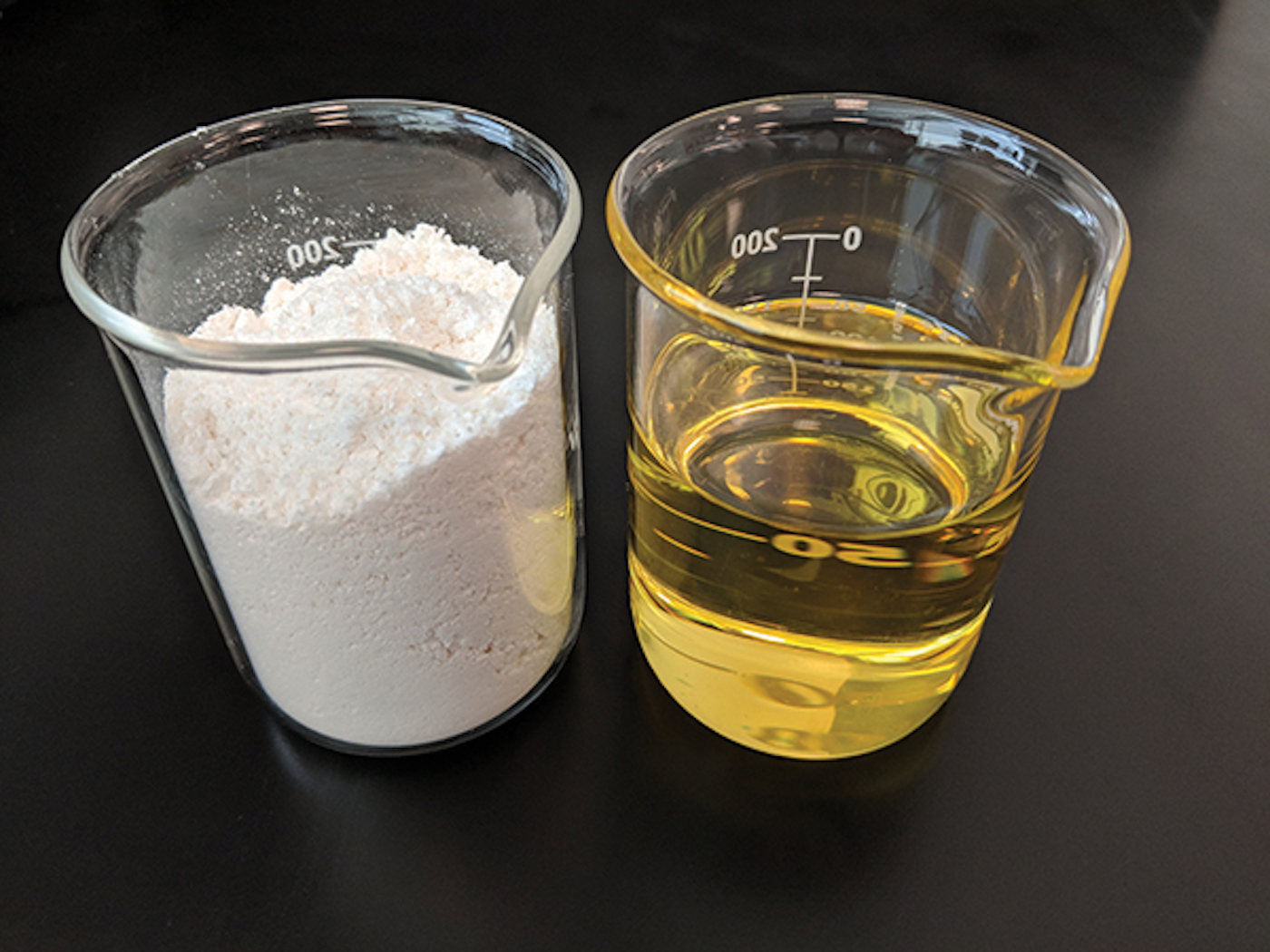

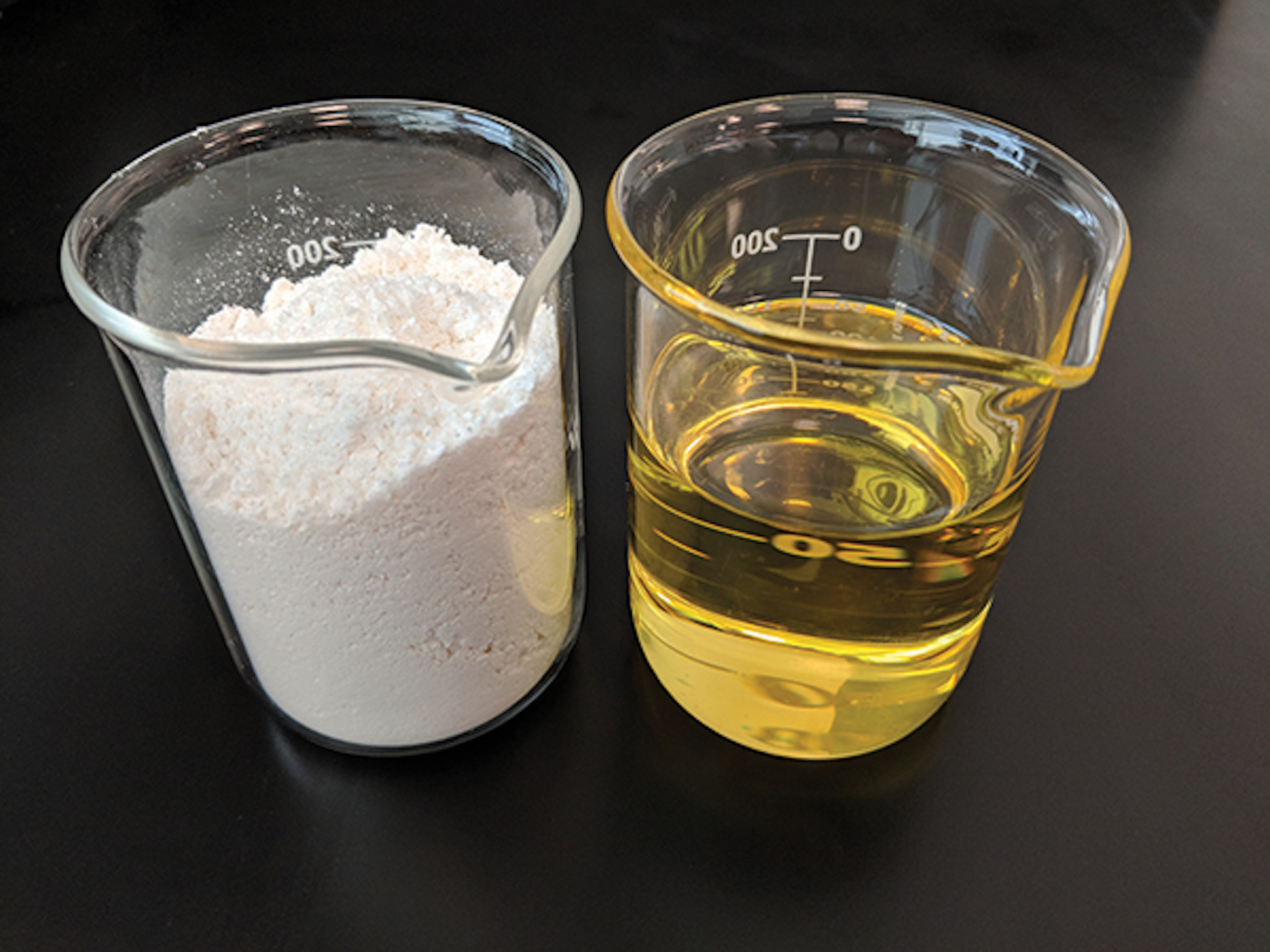

Dried algae biomass grown in fermentation tanks in the absence of light negates the need to use green chlorophyll for this oil-producing micro-algae. Once harvested, the oil has the exact appearance of any typical vegetable oil, with no flavor and no scent. The beaker on the right contains pure triglyceride algae oil that was extracted from dried algal biomass. Checkerspot’s unique strains of micro-algae can produce a range of previously unavailable and unexplored fatty acids to meet untapped material performance and sustainability benefits.

Other companies have introduced sustainable materials before. Entropy recently came out with a bio-based resin called Super Sap. And Niche Snowboards, using a product called Recyclamine, which allows for reverse molding (dissolving) the resin and recapturing materials, recently debuted a 100-percent recyclable/reusable snowboard. But Checkerspot is unique in tackling the base materials. It could be the change many in the ski industry have been looking for.

“As you can imagine, we have customers that are really interested in our efforts around sustainability,” says Mike Adams, VP and commercial director of Amer Sports, the parent company of Atomic, Salomon and Armada. “From my standpoint, what I’ve been working on and what I see more is the end-of-life part of it. Not so much replacing materials in production, which is obviously a whole new area, and really interesting.”

Amer has an extensive recycling program to re-purpose leftover materials and energy from the manufacturing process at their Altenmarkt, Austria, factory, which produces 400,000 skis a year. Amer’s most aggressive initiatives, however, revolve around making the facility more efficient. The factory has weened completely off oil. Its electricity comes entirely from renewable resources, and it shares a biomass facility with the local community that provides energy to the factory in the summer, when most skis are made, and heat to the surrounding towns in the winter. The company would like to do more, but so far haven’t found a workable solution. “On a regular basis, we are searching all the materials” for more sustainable options, says Helmut Holzer, Atomic’s director of anticipation and advanced research. “So far we haven’t gotten any good results.” Because the ski industry is relatively small, Helmut adds that the larger raw materials suppliers aren’t interested in developing more sustainable products, specifically, for such a niche market.

DPS’ Phantom cure station at its Salt Lake City factory.

Efficiency is the primary initiative for smaller factories as well. As owners of their own factory in Salt Lake City, DPS has more control over the construction process than other small brands. “We have a very active campaign to use additive manufacturing methods to not only reduce cost but reduce the amount of landfill created by typical subtractive manufacturing processes,” says Peter Turner, director of engineering for DPS. The company also has more flexibility when it comes to material choices, which has allowed it to be a pioneer in how carbon fiber—great for performance, yet environmentally toxic—is implemented into ski design, as well as develop its Phantom waxless base treatment as a less toxic alternative to traditional waxes.

Turner says DPS remains interested in exploring better and more sustainable materials, but that currently, its best course is through choosing its suppliers. “Actually a ski is quite inert to the environment and they are not at all toxic,” Turner contends. “However, some of the raw materials can be toxic in their manufacture and require good controls to protect the environment [from them]. In recognition of the good environmental laws we have in this country and in Europe, we try to source all of our materials from those regions.”

This, unfortunately, leaves sustainability in the hands of politicians, who can be subject to lobbying and corruption. (For examples, Google Pruitt, Scott.)

“Right now, the go-to-action for sustainability in the ski and snowboard industry is to donate a portion of your proceeds to a non-profit, and their goal is to run the message up the pole to see if we can make some laws that govern some of these carbon-impacting principles,” says Sterbenz. Meanwhile, the outdoor lobby, while improving, still pales in comparison to the influence wielded by fossil fuel advocates.

Raw materials organized in Atomic’s ski factory in Austria.

A similar conundrum exists when it comes to influencing material suppliers. In the industrial materials world, the ski industry is minuscule. So far, large suppliers have not found it worth their time to develop something more environmentally friendly specifically for such a small market, even if that market demands it and is willing to pay for it.

When a new supplier does try to enter the ski market, it’s often without the knowledge of what the final product will endure once it’s put on snow. “Quite often, contacts want to do something for the ski industry and have no idea about it,” says Holzer. “It’s not that easy. We have our product used in very difficult conditions. It’s icy, there’s water, it’s freezing, it’s abrasion resistant, so it’s very specific materials you are using, and to replace those, so far we are not able to find a material which we could use.”

With Sterbenz and snowboard industry veteran Dan Malmrose on board, Checkerspot is in the process of building a testing facility in Salt Lake City, which will include a press to build prototypes. “It’s one thing to put a new material into something and then make an amazing marketing plan around it,” says Malmrose. “But it’s another thing to validate it [with data]. One of the things we’re doing here is trying to set up some serious validation efforts so we have hard data that shows this material isn’t going to blow up.”

Matt Sterbenz, along with material scientist Lauren Slutzky, bringing some of that ski industry humor to the Checkerspot labs.

Sterbenz believes Checkerspot’s engineers will have the product tested and ready in 12 to 24 months. But he’s also aware it could take years for it to be implemented in large scale. “It’s a very rigid environment,” he says of ski manufacturing. “They want to make you any ski you want as long as it comes from the same deck of materials that they have proven are stable to work with because they’re on the hook if they fall apart.”

Holzer confirms it likely would take time to break into the Amer factory, but says they have systems in place. “Testing internally would go quite fast,” he says. From there, Holzer continues, they would try it out in a single model for at least a season, before maybe integrating it into a series. “So, testing it could take a couple of months, then it must be at least one winter in the field and then it would take another season to implement.” Even at that point, Holzer says it wouldn’t be used across the entire factory immediately. “We would have a specific model, specific range or even a specific brand,” where the product would be introduced, he says.

Depending on what adjustments might be needed to the factory’s equipment, it could take even longer. “If we have to invest in molds then it could take at least four, five years because that’s our timing where we are replacing all our molds,” Holzer says. “If we have to change the press parameters, like temperature or timing of the press, then that would be another very tricky, and maybe [time-consuming] development.”

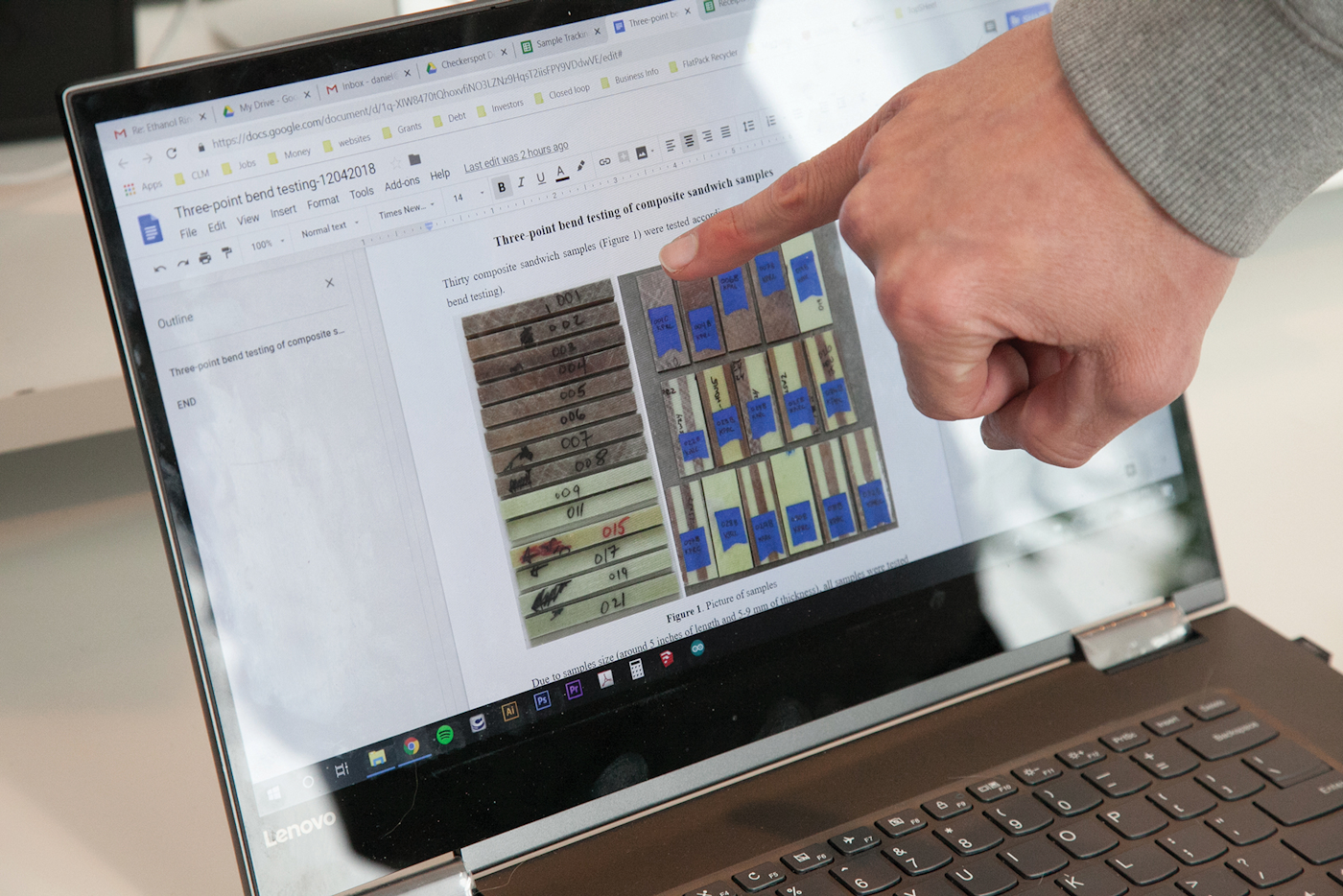

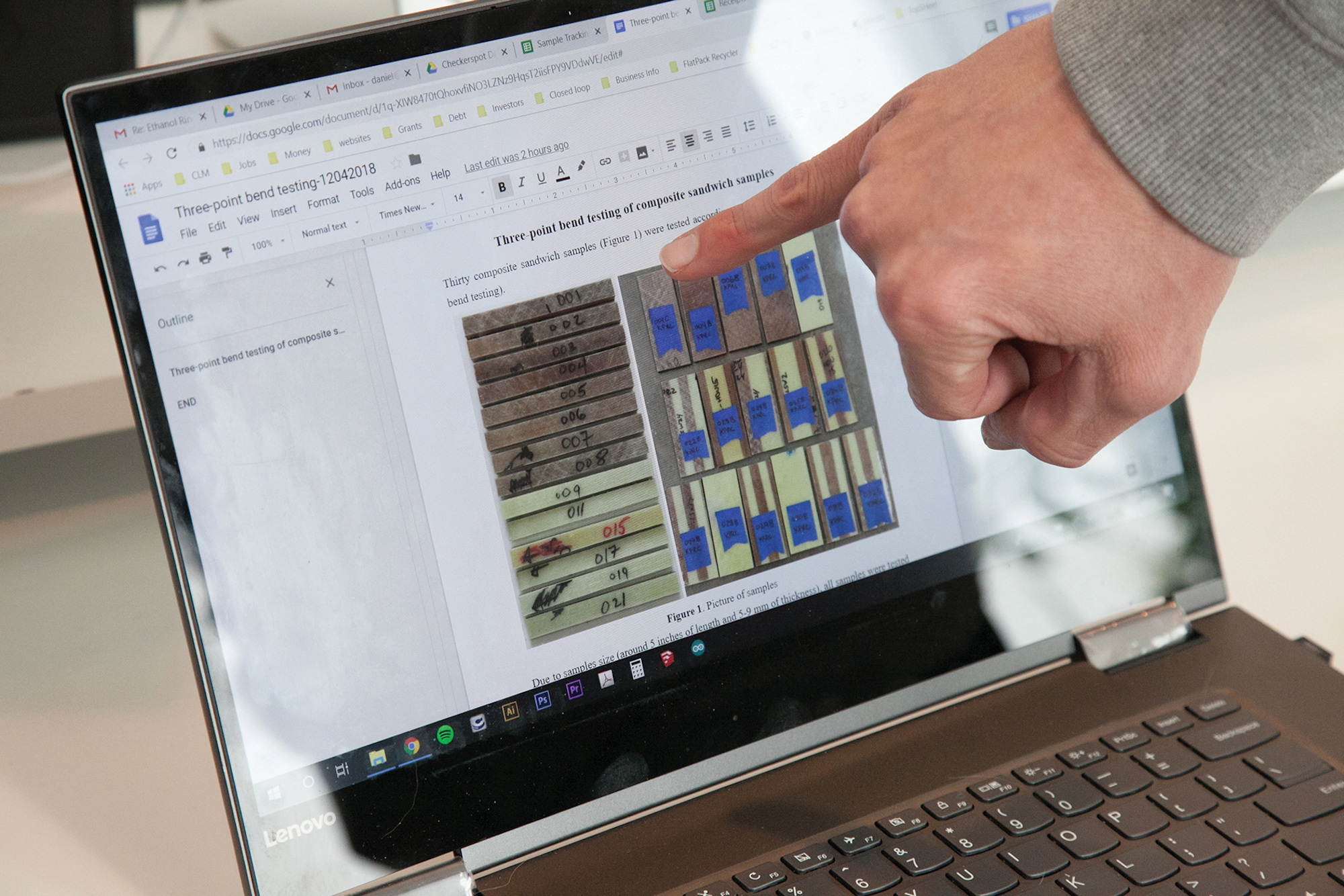

Taking a look at data from a three-point bending test of composite sandwich samples using Checkerspot concepts.

“The capital investment when you change this sort of thing would be enormous,” Adams says. “It would be a massive undertaking.” Massive, but not insurmountable. “I think everyone is interested,” he adds.

From the consumer to the factory, there is a growing demand in the ski industry that the products we use to connect with the environment be friendlier to it. Checkerspot won’t be a cure-all, but it could be a massive step forward. Within the next decade, we may be able to take in nature from the summit without having to ignore the nature of the equipment that got us there. “There’s energy consumption, there are a variety of ways in which harmful things get into the production of materials today. We’re by no means perfect out of the gates,” Sterbenz says. “I think the big thing is that the technology comes from a renewable resource that has a lighter impact on the planet. But we’re motivated by the superior properties that we can obtain. That’s what’s exciting for us.”

“The outdoor industry is ripe for technological advancements at this level,” Sterbenz continues. “This opportunity is something that could be widely disruptive. And necessary, I think, in the industry.”

![[GIVEAWAY] Win a YoColorado X Coors Banquet & Liberty Skis Prize Package](https://www.datocms-assets.com/163516/1769630228-pastedgraphic-3.png?w=200&h=200&fit=crop)