Let’s face it: ski outerwear is complicated. And, well, it should be, because we’re talking about products that are designed to battle some of the harshest elements on Earth. From their waterproofing attributes to emphasis on insulation to all of the useful pockets and other additions we see on jackets and pants these days, understanding everything isn’t super easy. So, we’ve decided to break down all of the relevant technology by way of a few exemplary products. When you buy your next kit, keep all of the information, below, in mind and always remember there’s a lot that goes into making these items.

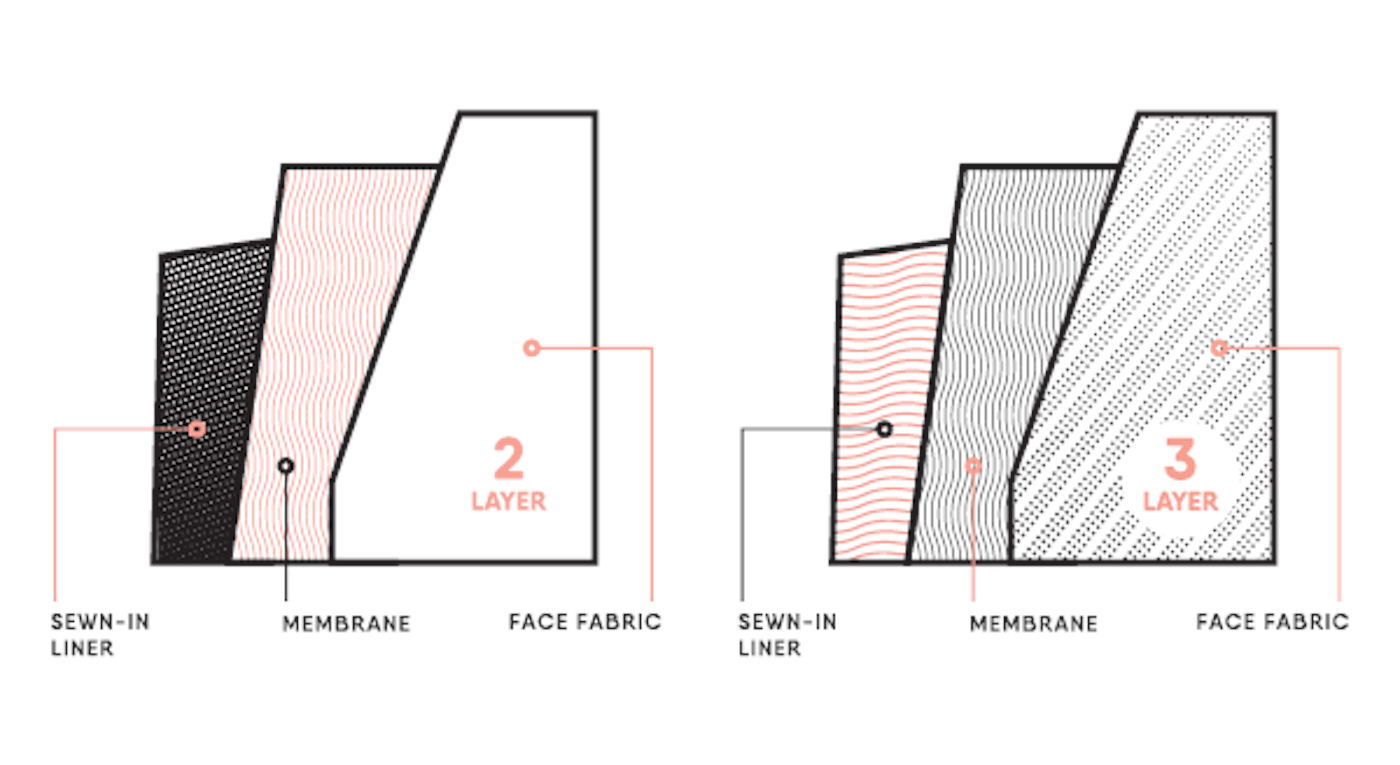

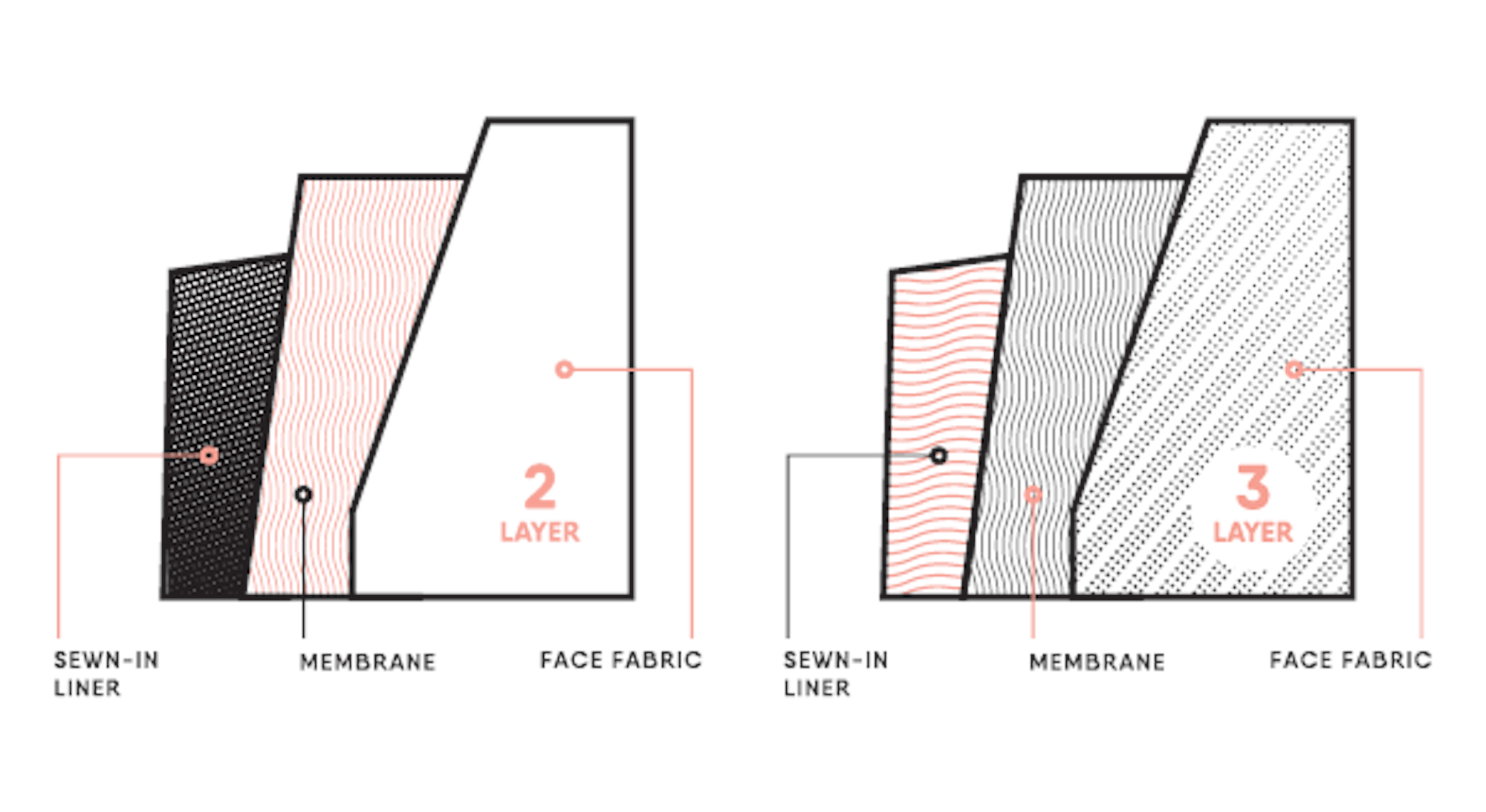

Two-layer vs. three-layer construction

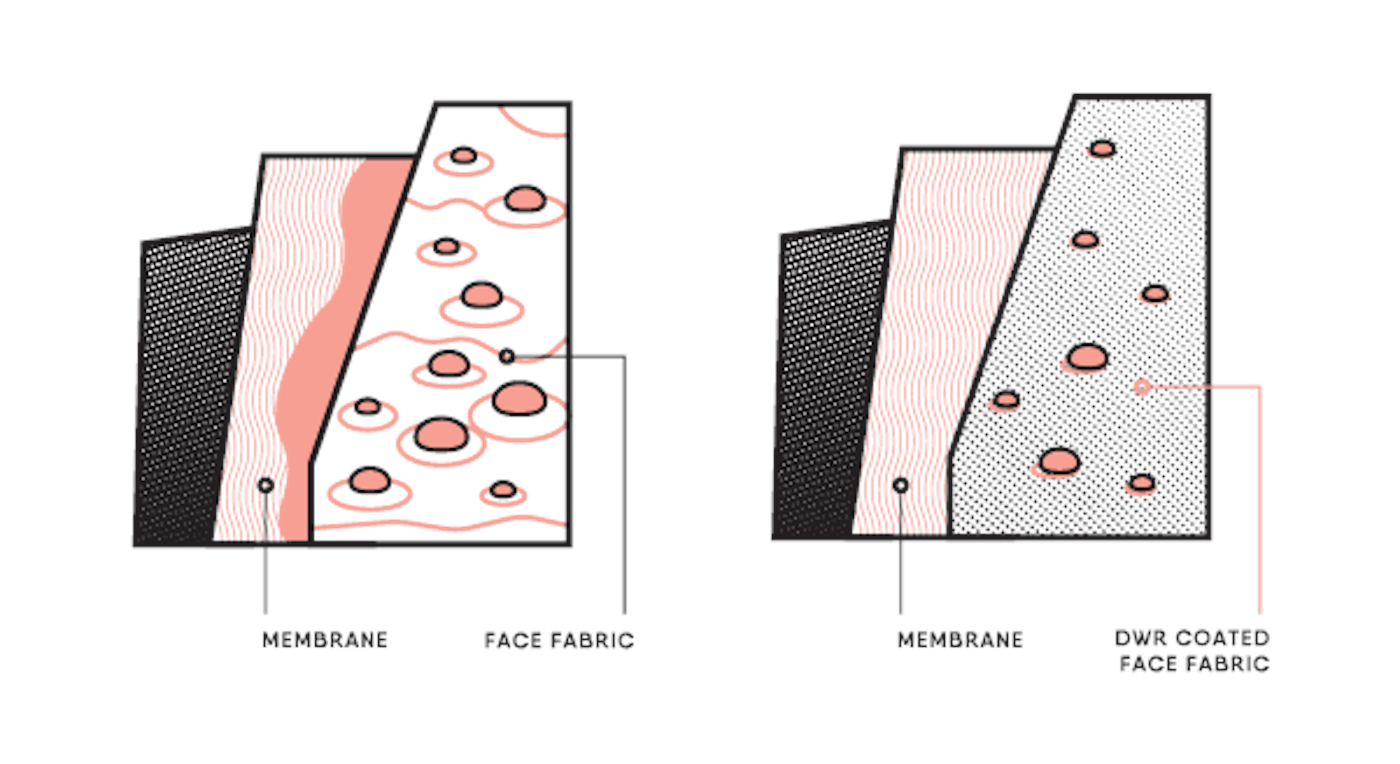

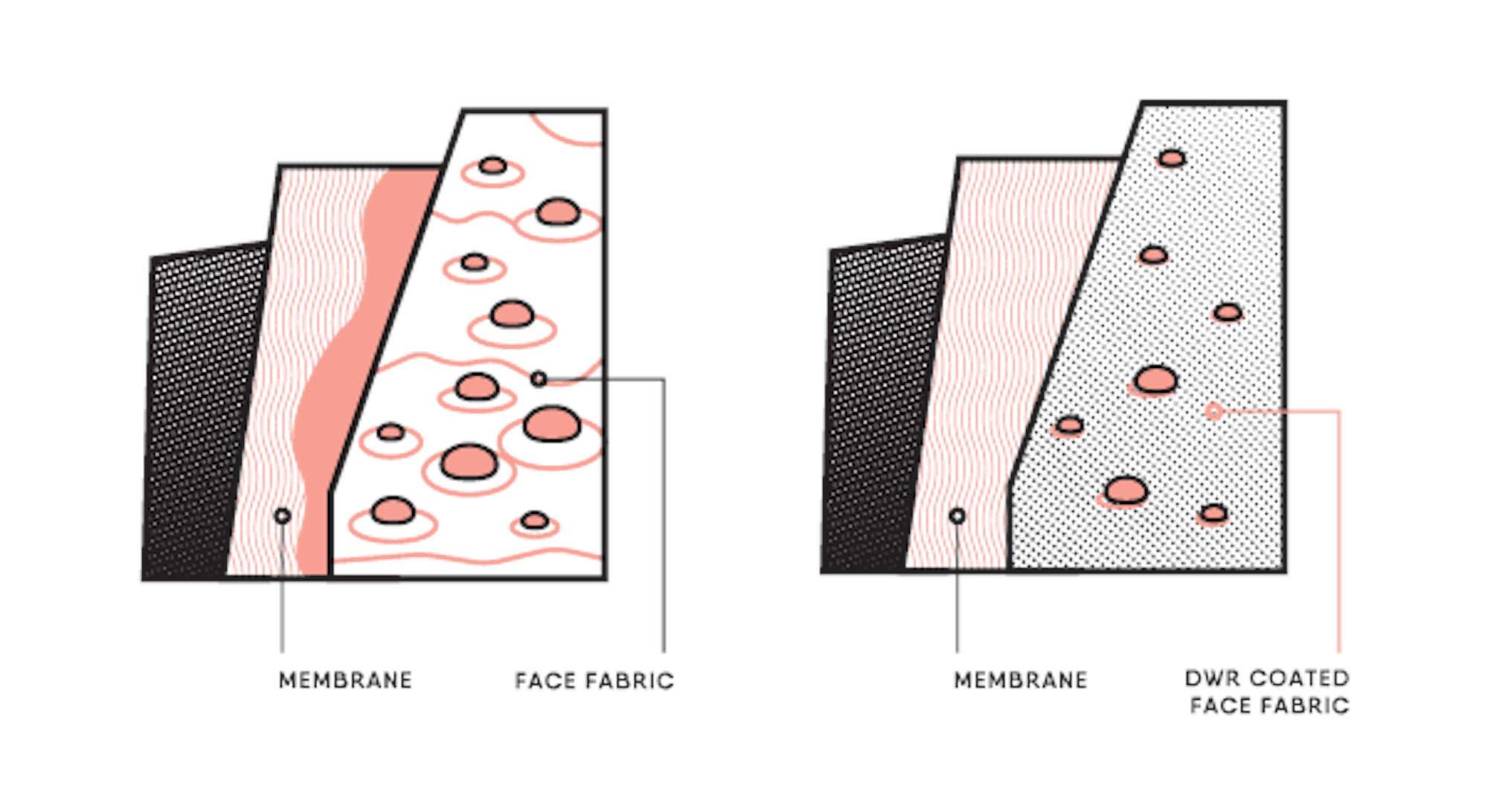

If you want something that can stand up to winter’s harshest storms, you’ll most likely be in the market for a two-layer (2L) or three-layer (3L) garment; this designation refers to the garment’s membrane and protective layers. Waterproof/breathable outerwear begins with an initial layer called the membrane (see the “How a membrane works” section below, for more info). The membrane is bonded to one or two other layers that prevent it from damage. The “face fabric” is the outer layer, typically comprised of nylon or polyester; meant to safeguard the membrane from wear and tear as well as dirt. The face fabric is also where manufacturers integrate colors and other stylistic aspects—making sure you look darn good out on the hill. A two-layer garment’s membrane and outer layer are bonded together and a sewn-in liner protects the membrane from weathering. Keep in mind that, despite their high quality, 3L garments in particular can be thin and usually require a layer or two underneath to stay warm.

To keep you warm without the need for tons of layering, insulation can be packed into the liner (see the “Insulation” section, below, for more). A two-layer construction is great for a run-of-the-mill day on the hill. Three-layer offerings, on the other hand, help provide a cool-down with warm weather and/or intense energy exertion, as well as serious protection against brutal winter weather. In a three-layer construction, the membrane is sandwiched between the outer layer and a moisture-wicking, breathable inner layer that helps keep you cool during periods of excessive exercise.

Insulation

The insulated ColdGear Reactor Hooded Jacket, utilizing Under Armour’s own synthetic ColdGear Reactor intelligent insulation. This insulation adapts to your varying body temperature throughout the day and keeps you comfortable no matter what—eliminating the need for putting on and taking off extra layers over and over.

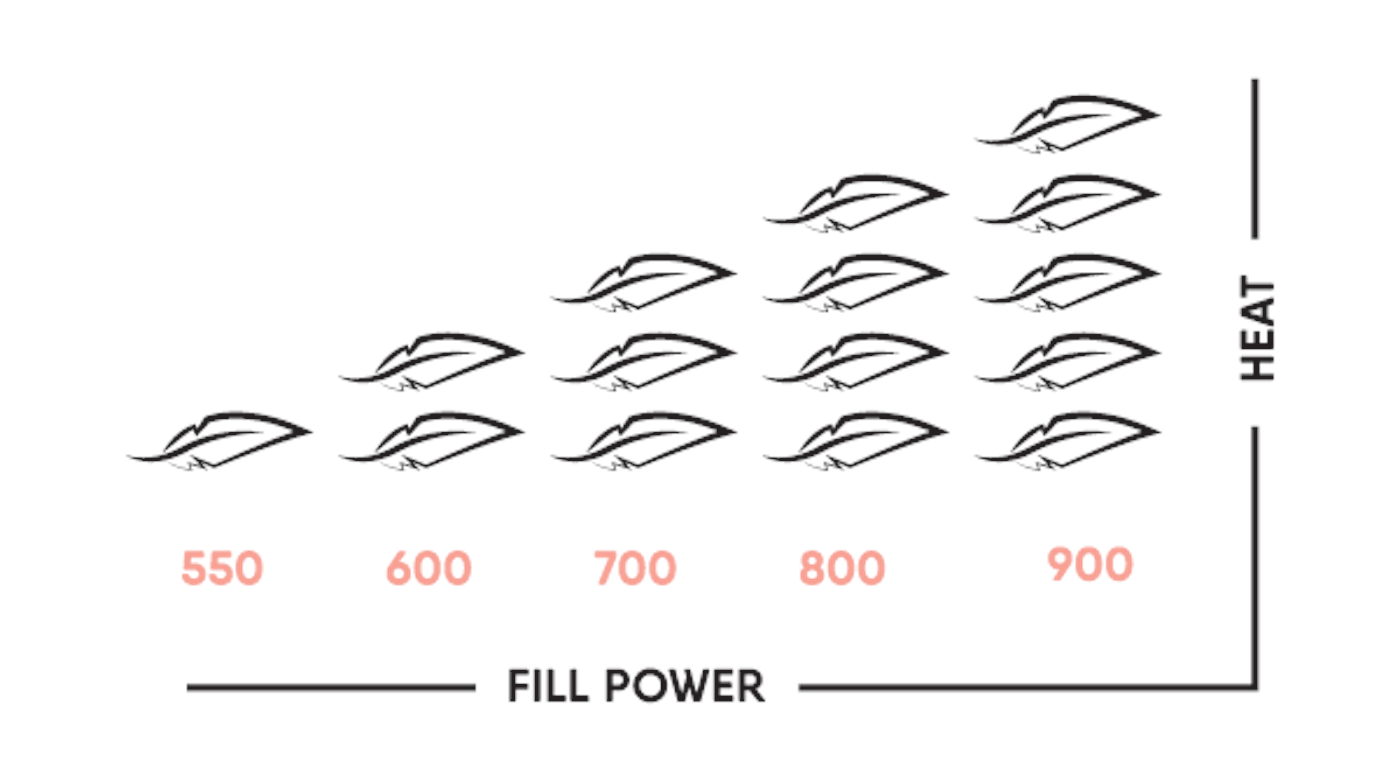

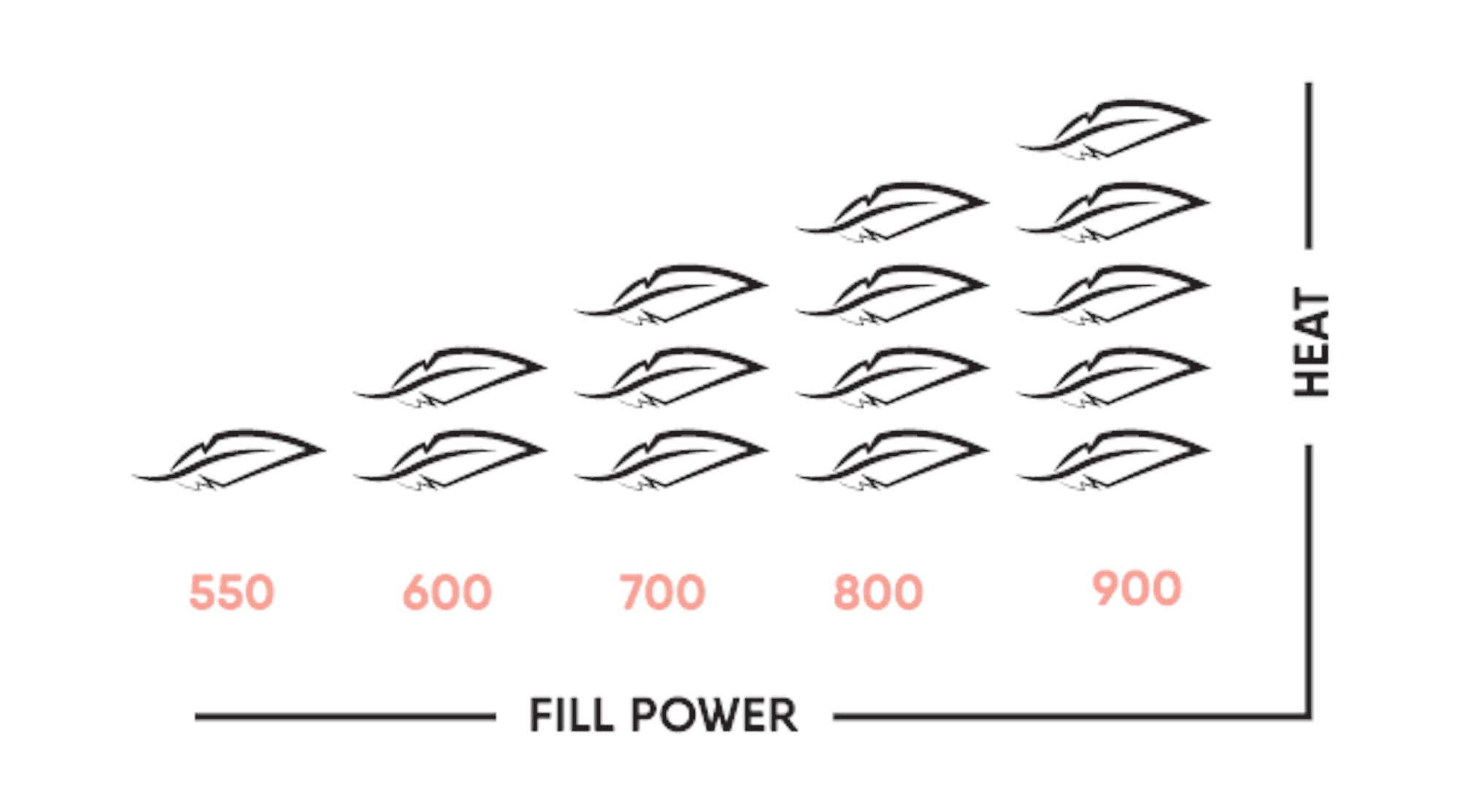

Just like a house, insulation provides and maintains warmth in a piece of outerwear. Insulated outerwear is filled with down—the warm, inner layer of feathers on a bird—or a synthetic insulator.

Let’s start with down: Its “fill power” is an indicator of its warmth. The number comes from a test in which one ounce of down is stuffed into a graduated cylinder. The volume it occupies, in cubic inches, is its fill power. This generally ranges from 500 to 800, the higher the number, the more warmth the garment will have. The advantage of down, in particular, is its warmth-to-weight ratio and its compressibility.

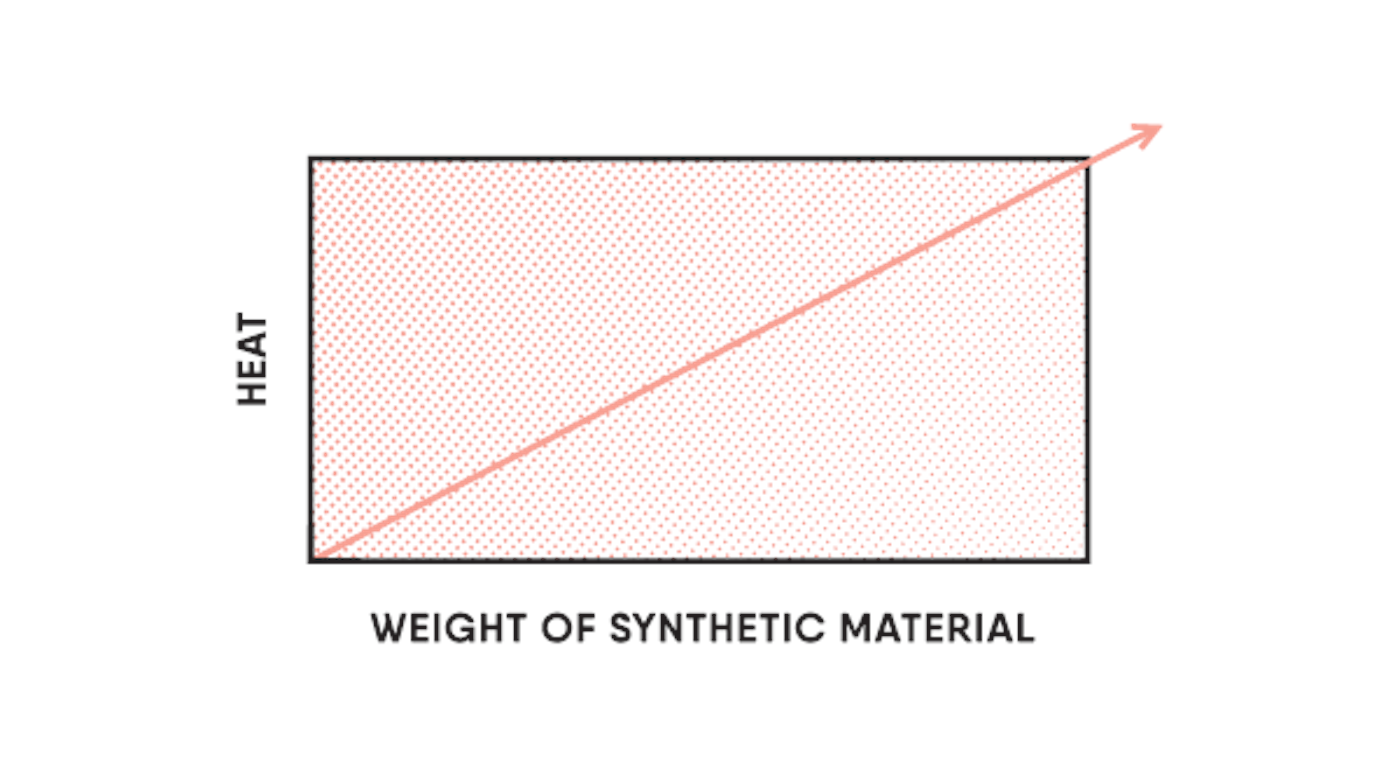

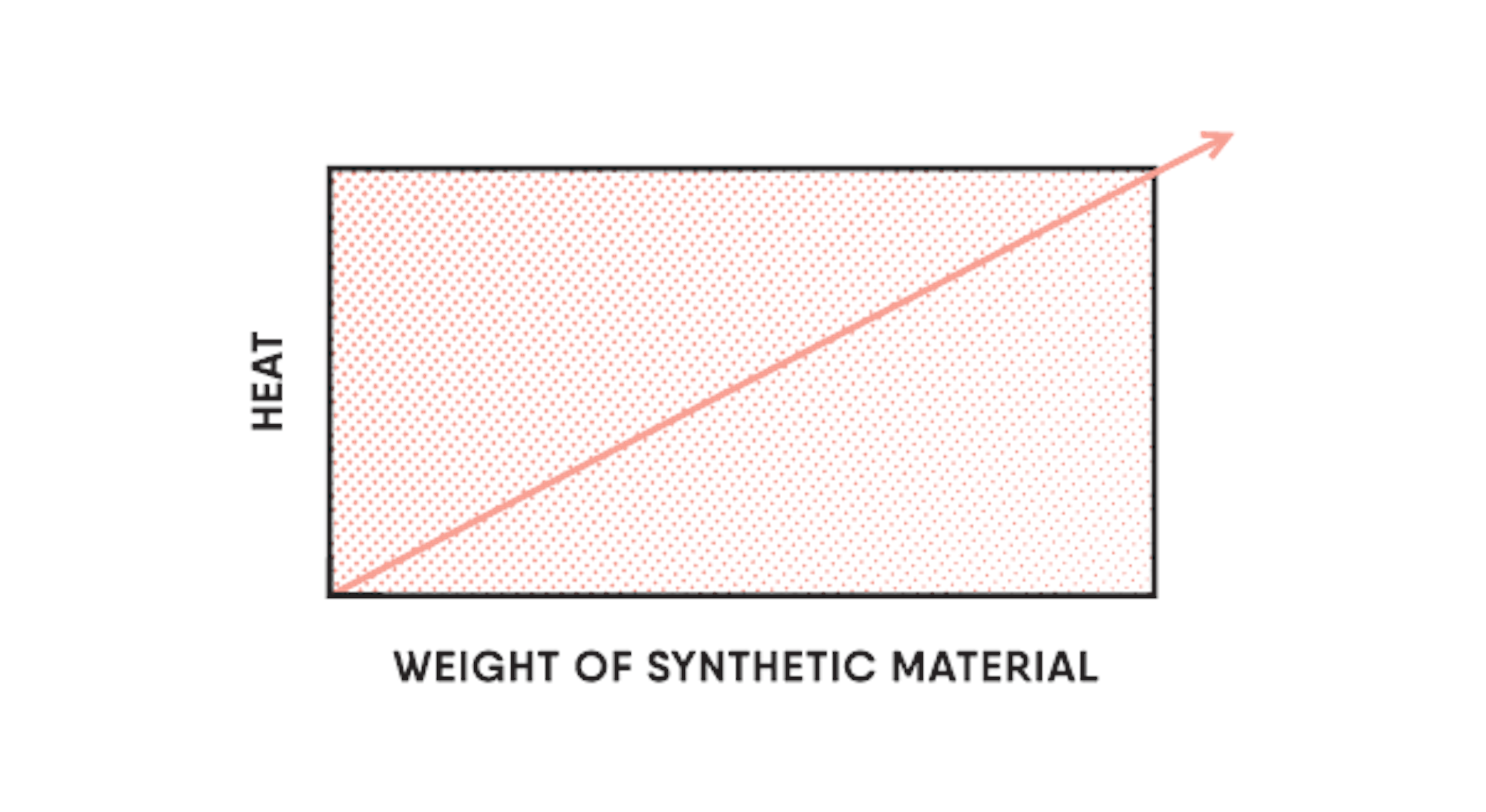

Synthetic insulation, on the other hand, is made up of ultra-thin polyester fibers. It’s not quite as warm and compressible as down, but it often repels water better. The rating system for synthetic insulation is measured as the weight in grams of a one-meter-by-one-meter sampling. If it has a higher weight, it’s warmer, and weights generally range from 40 to 120 grams.

Manufacturers usually place heavier insulation in areas susceptible to heat loss, such as the torso and hood, letting the warmer parts of your body—like your armpits—breathe a bit more.

Durable water repellant

A jacket or pant’s membrane may be waterproof but its face fabric is not. So, if water drenches the outer layer, the membrane essentially has no purpose. In order to prevent this from happening, a durable water repellent (DWR) is coated on the outer layer. Over time dirt, oil and abrasion will hinder the DWR’s performance. The coating will have to be reactivated by a spray-on or wash-in water-repellent treatment, like Nikwax, and then tossed in the dryer.

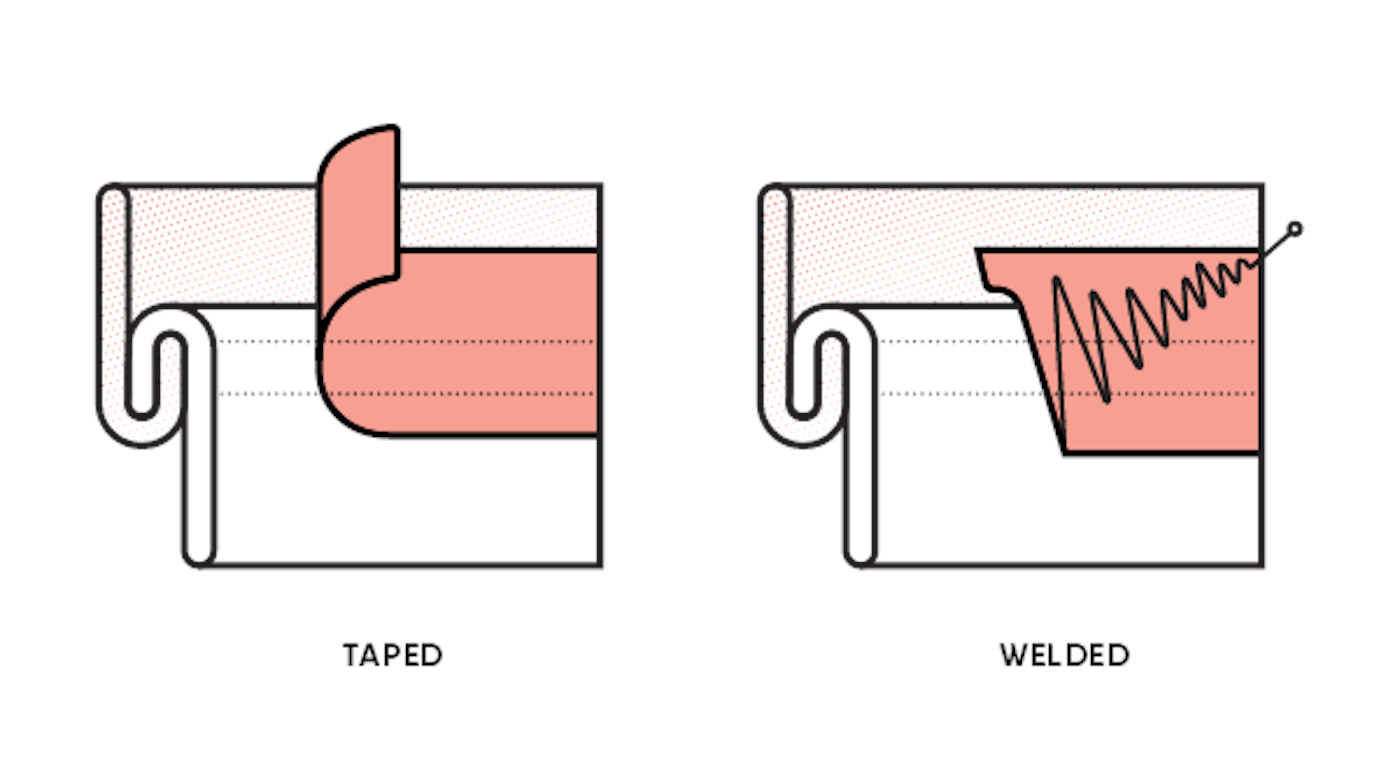

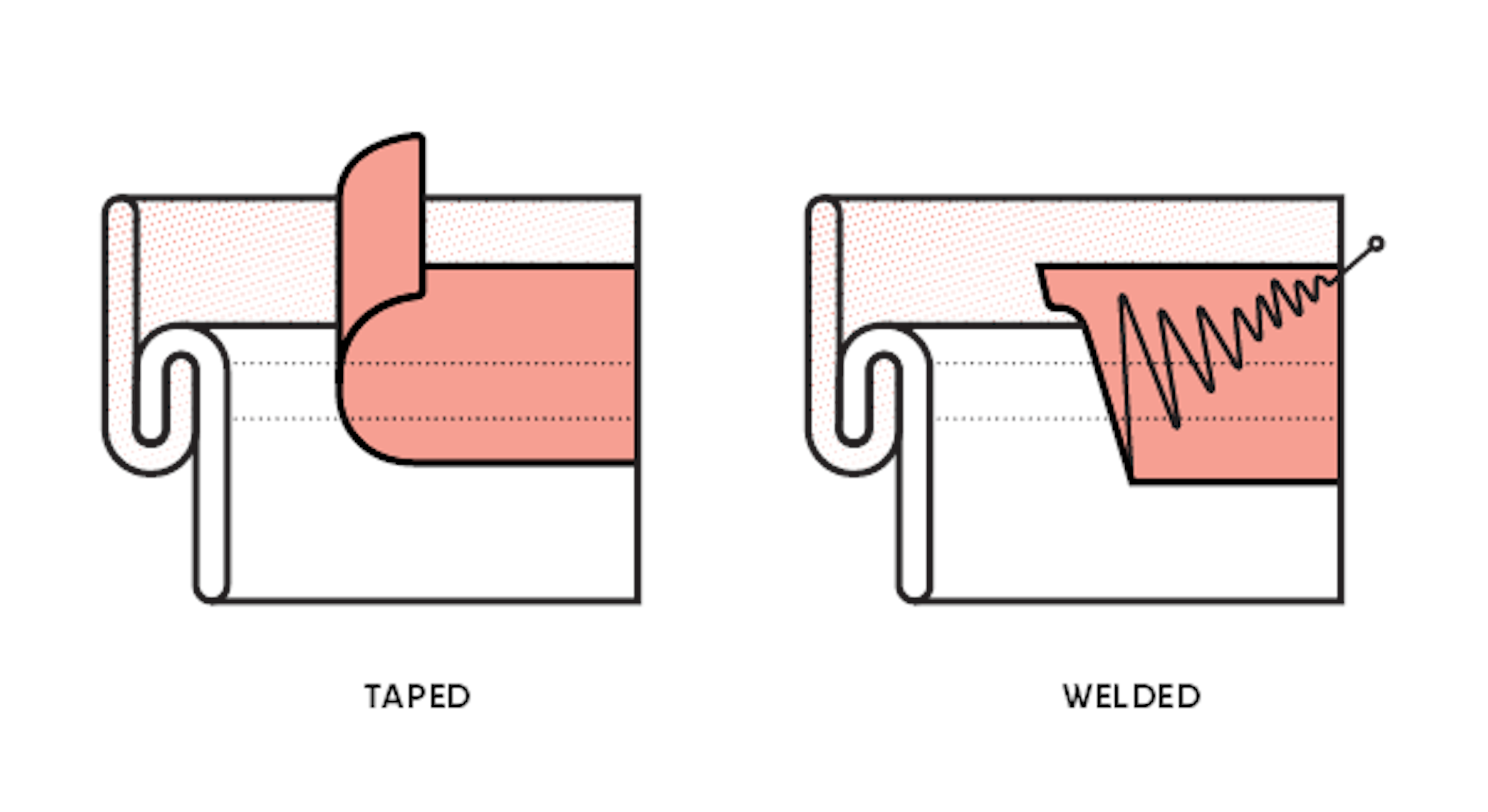

Seam taping and welding

When outerwear is sewn together, needle holes are pierced through the membrane around the seams and zippers. The holes are to water as Bill Buckner is to baseballs—highly penetrable. Those holes are just what water needs to seep into your clothing and ruin your day. To solve this problem, seams are often taped over to cover up the holes. In the most premium outerwear, seams are eliminated completely through a welding process known as seam sealing. Sometimes, manufacturers seam seal only in the areas most prone to soaking, like the hood or shoulders, which is called “strategic” or “critical” sealing. Strategic sealing will hold up to mild weather, no problem. Fully sealed seams, though, are essential for those who regularly ski in wet climates and harsh environments.

Waterproof and breathability ratings

The Chugach GTX Jacket, equipped with a 28K/20K waterproof/breathability rating. In other words, this thing goes above and beyond the industry standard. In a scale of 1 to awesome, it’s undoubtedly awesome.

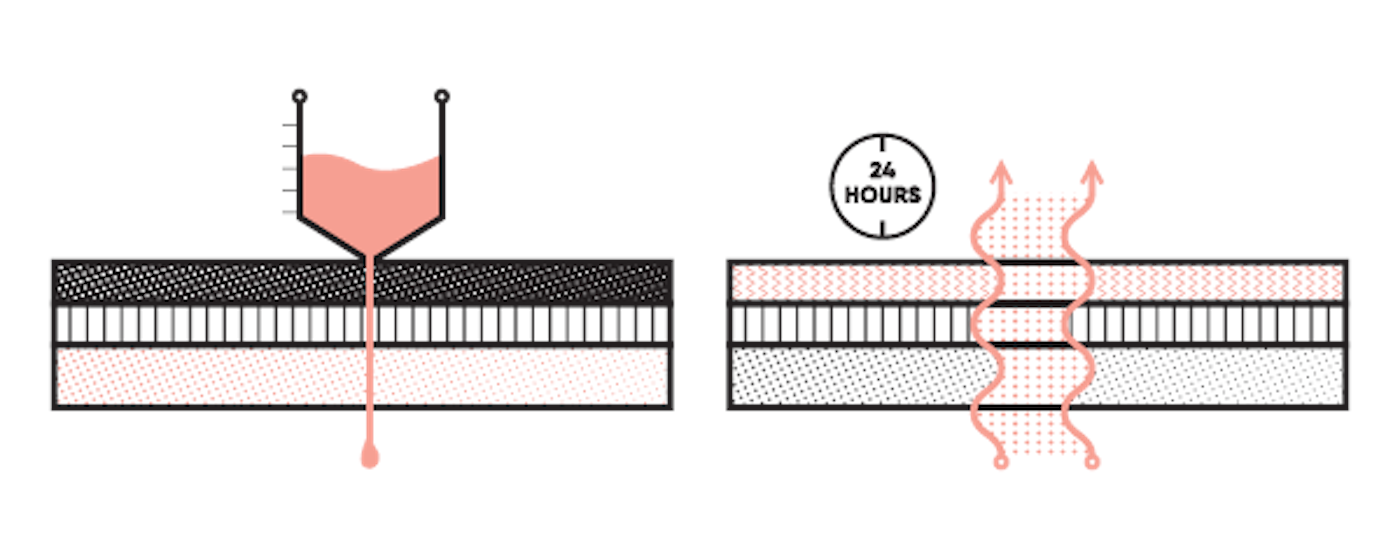

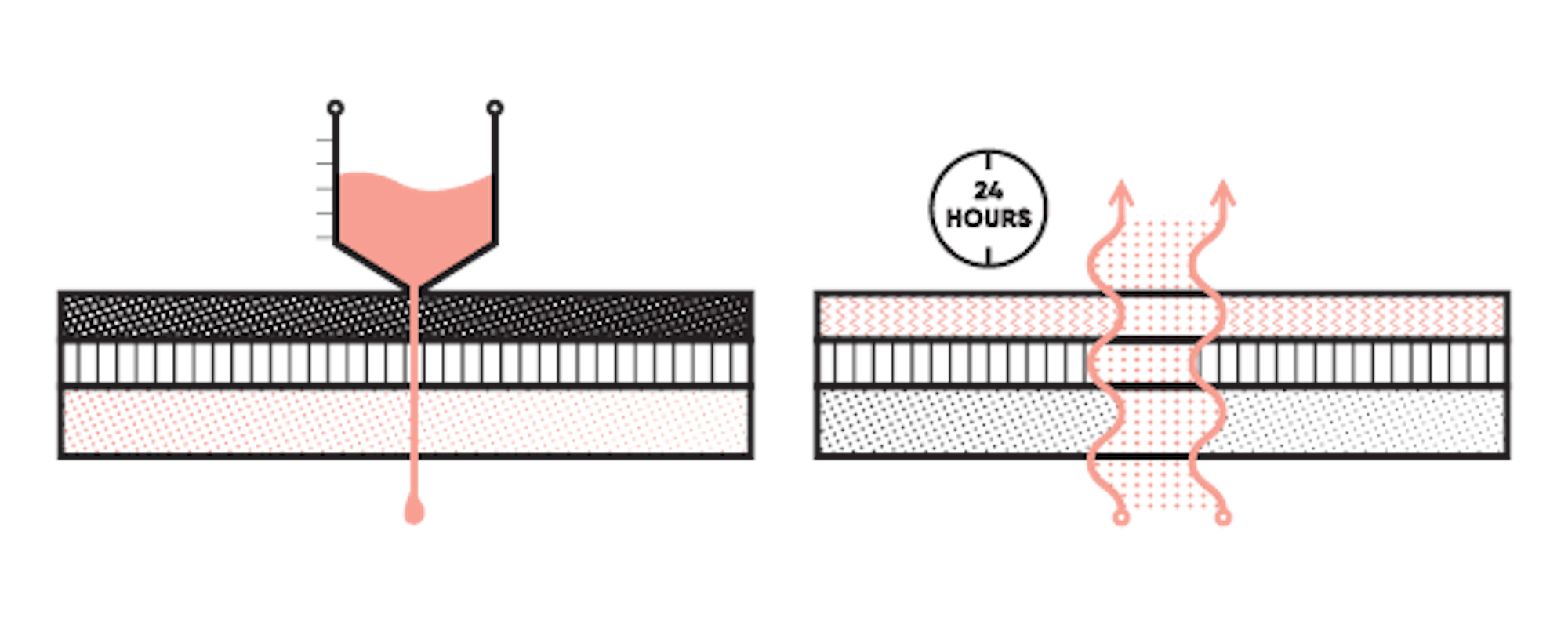

A water column test determines the waterproof rating you’ll see in reviews on the following pages. The test consists of a one-inch square tube that is positioned on top of a piece of fabric. The tube is then filled with water until the liquid penetrates the membrane. The amount, in millimeters, that the fabric resists before ultimately leaking is its rating, e.g., 15,000 mm or 15K.

A garment’s breathability rating is determined by a test that measures how much water vapor can pass through a square meter of fabric or membrane over the course of 24 hours. Results are measured in grams per meter squared per day. For example, 15,000 g/m2/d would equate to a 15K rating. (Keep that knowledge in your back pocket; it’ll impress someone on the chairlift.) At the bare minimum, your outerwear should be rated at 5K/5K. If you’re regularly skiing amid inclement weather, a 10K/10K minimum is suggested but 15K/15K would be a smart bet. And if you’re consistently exerting a great deal of energy on the skin track or skiing in volatile high alpine environments, 20K/20K or above is a no-brainer.

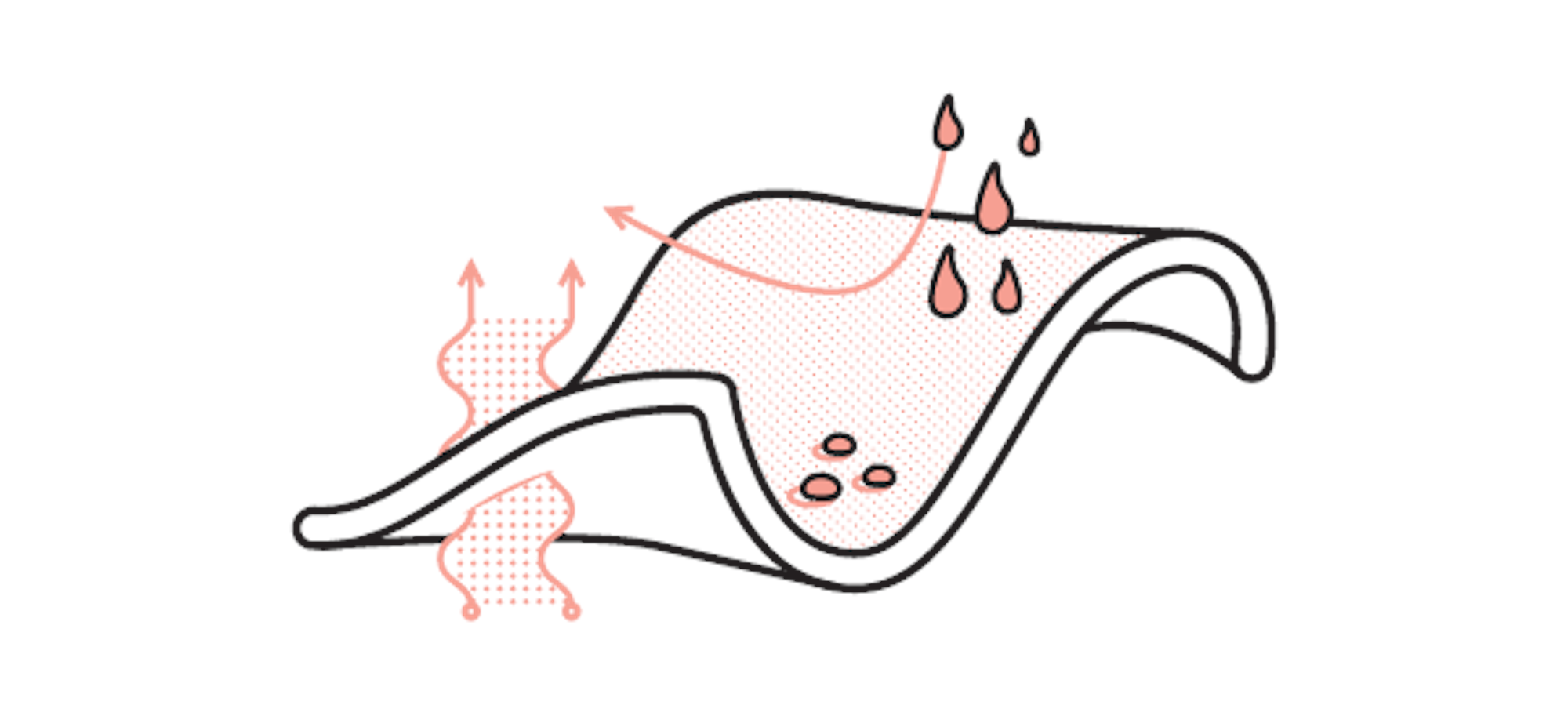

How a membrane works

Inside of this Chugach GTX Jacket is a bombproof, yet totally breathable membrane that adapts to your body heat.

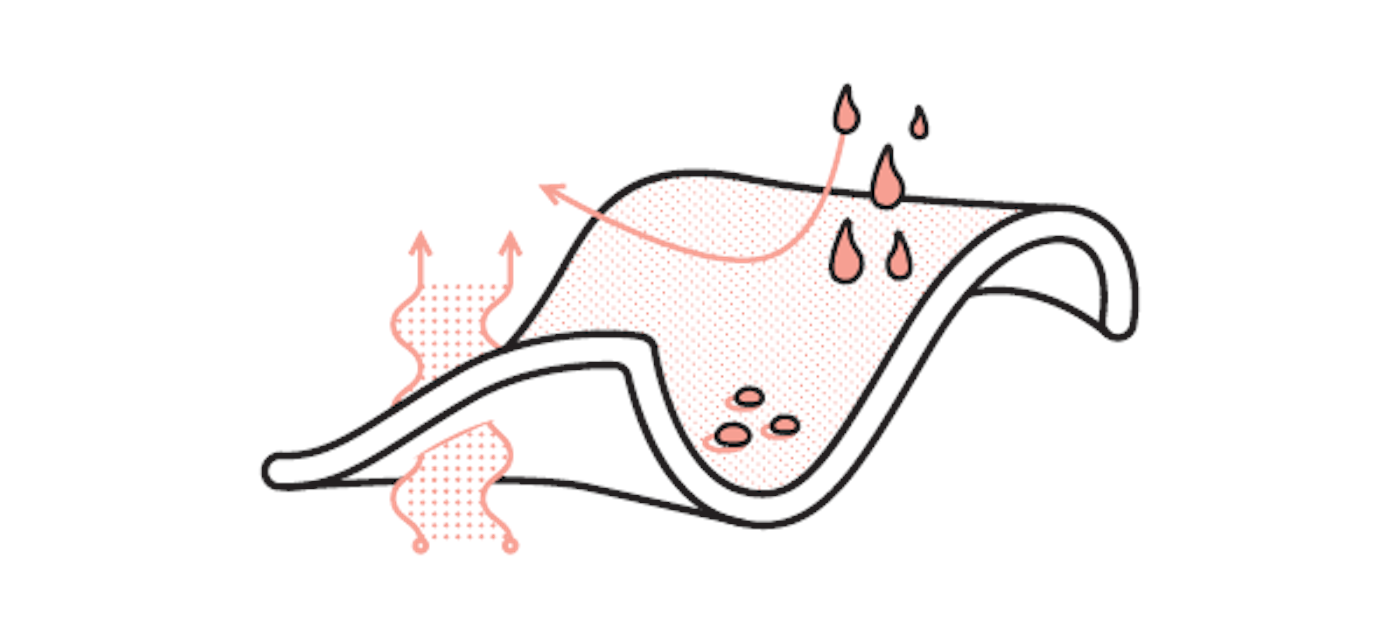

The membrane makes the world go ’round. It’s essential for the membrane to be both protective and permeable. To achieve this end, any membrane worth your dollar should feature minuscule holes small enough to block water droplets from entering but large enough to allow vapor molecules to escape. It’s a delicate balance. The membrane is kept clean and free of blockage thanks to protection of the face fabric.

Extra nice-to-haves

Many manufacturers go the extra mile by adding useful features to their outerwear on top of the high-quality materials we’ve been discussing. For example, Under Armour includes tons of vents on its jackets and pants to help you regulated your temperature on high-exertion days. Additionally, they throw in handy things like powder skirts, boot gussets, boot-friendly zippers, adjustable hems and goggle wipes to really provide skiers with everything they need.

A powder skirt accompanied by an adjustable hem on the Chugach GTX Jacket. The former snaps together around your waist to keep snow out, while the latter tightens the bottom of the jacket to further prevent moisture from coming in.

Boot-friendly zippers and gussets on the Chugach GTX Bibs. The zippers allow you to access your buckles without hiking up your pants, while also providing a custom fit to your boot’s size. The gussets act as protection from your edges and other obstacles that might scuff up or tear the pants.

Inner-thigh vents on the Chugach GTX Bibs, which are utilizied via zippers so you can let extra warmth out or keep warmth in.

Side vents on the Chugach GTX Jacket allow you to air out when things get hot and steamy. When you’re comfortable again, simply zip them closed to maintain warmth.

Hopefully, this helps you navigate the wild world of ski gear—leading you to the perfect outerwear kit so you can take on this winter like a champ. And if you have any questions after reading all of this, we’d be happy to answer them. Shoot us an email anytime (gearexpert@freeskier.com) and our knowledgable squad will get back to you ASAP.

To see more about the gear used in this article, follow the links, below.

Under Armour Chugach GTX Jacket

![[GIVEAWAY] Win a Head-to-Toe Ski Setup from IFSA](https://www.datocms-assets.com/163516/1765920344-ifsa.jpg?w=200&h=200&fit=crop)

![[GIVEAWAY] Win a Legendary Ski Trip with Icelantic's Road to the Rocks](https://www.datocms-assets.com/163516/1765233064-r2r26_freeskier_leaderboard1.jpg?w=200&h=200&fit=crop)

![[GIVEAWAY] Win a Legendary Ski Trip with Icelantic's Road to the Rocks](https://www.datocms-assets.com/163516/1765233064-r2r26_freeskier_leaderboard1.jpg?auto=format&w=400&h=300&fit=crop&crop=faces,entropy)

![[GIVEAWAY] Win a Head-to-Toe Ski Setup from IFSA](https://www.datocms-assets.com/163516/1765920344-ifsa.jpg?auto=format&w=400&h=300&fit=crop&crop=faces,entropy)