Click, Click, Click.

A round dial turns clockwise—a wire lace coils around itself. Completing a full circle, proudly bearing the bold letters BOA. With precise 0.25 mm adjustments, you turn the dial on your boot, tailoring it to your exact fit. As a response, the plastic shell gently molds around your foot, securing it snugly. You wiggle your toes, and it feels…different. No discomfort. A sheepish glance at your traditional overlap boots fills you with a pang of guilt. You’ve succumbed to the BOA influence.

BOA has made its grand entrance into the alpine ski market, infiltrating it with its signature technology. The brand is no stranger to the outdoor industry, particularly in the realm of snow sports. Chances are, you already own some BOA gear in your closet. From work boots to golf shoes, snowboard boots and beyond, BOA boasts an extensive range of innovative products. The brand began in Steamboat Springs, Colorado, by snowboarder Gary Hammerslag with an aim to increase performance. Now, after two decades of success, the ever-growing BOA team, now lead by CEO R. Shawn Neville, set its sights on the alpine ski market, swapping your two lower buckles for a wire lace that’s strong enough to hold a chair lift. Although that impressive factoid isn’t the primary purpose of these new boots, it’s undeniably cool.

The most effective way to convey the H+i1 dial platform is through a simple hand motion. Cup your hands in a circle, and notice how your fingers naturally overlap with one hand resting on top of the other. As you gradually tighten the circle, the shape remains intact. This very motion is what the H+i1 technology mimics. As you twist the BOA dial tighter, the boot envelops your foot, akin to the movement of your hands overlapping. Traditional buckle boots fall short in this regard.

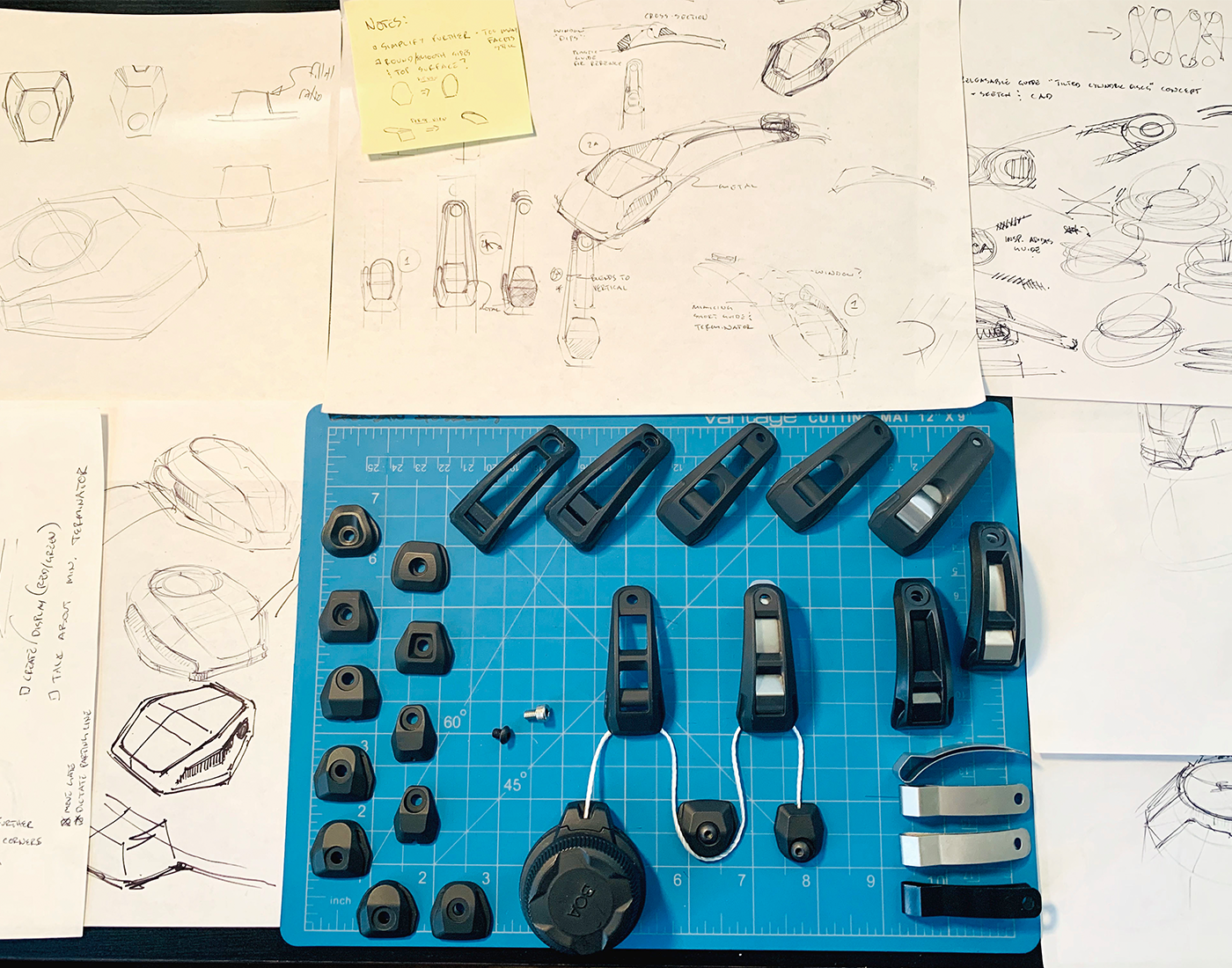

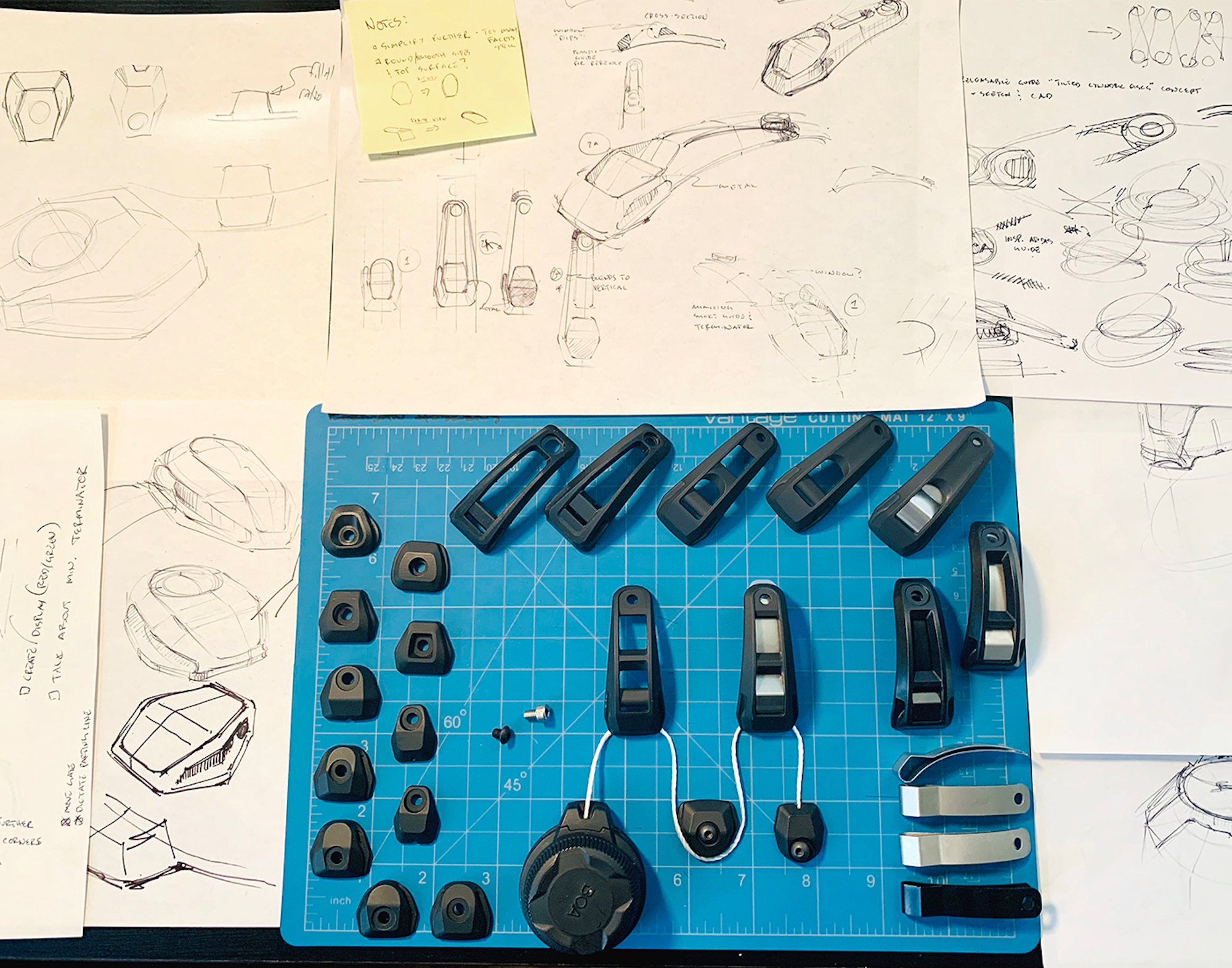

A look into the engineering behind BOA

Having spent six years in the realm of research and development, the new alpine H+i1 system has finally reached perfection and is hitting the shelves. Available across four renowned brands—K2, Fischer, Atomic and Salomon—these boots offer reduced pressure points, a 10 percent improvement in the rate of force production at turn initiation and a sleeker profile compared to traditional bindings. “As we optimized the boot design and H+i1 system, we gathered pressure mapping and on-snow performance data with our Performance Fit Lab team that quantified our feelings,” explains Dave Dickensheets, BOA’s VP of Product Development. “The measured improvements in heel hold and edge-to-edge control confirmed we improved boot fit and offered skiers next-level performance.” K2, Fischer, Atomic and Salomon stand at the forefront of an exciting era in alpine skiing.

We’ll be the first to admit that change doesn’t come easily in this industry, especially in something as personal as ski boots. However, since the dawn of our sport, skiing has taken on numerous forms, some for better and some for worse. In the 1800s, Norwegian hunters and farmers had no qualms about fastening their daily shoes to a pair of planks using a single leather strap. Fancy boots were the least of their concern as they embarked on the first ski turns known to man. As the years ticked by, Scandinavians introduced heel bindings, and local cobblers began customizing ski boots, still predominantly made of leather until 1962. It was then that Bob Lange revolutionized the ski world with the introduction of the plastic shell boot. The switch made boots more durable and waterproof. After a few iterations, boots found their rhythm. Now, in the ongoing timeline of skiing, this year marks another significant milestone.

BOA’s headquarters in Denver, CO

So, why fix what ain’t broke? While ski boot technology has been dialed in for decades, there is always room for improvement. One of the most common grievances among seasoned and new skiers is foot pain. Their boots squeeze their toes, their shins are constricted, and their arches are on fire. BOA kept this in mind and aimed not to reinvent the ski boot but rather refine it to achieve a personalize precision fit tailored to the individual. This approach has yielded proven benefits that significantly enhance overall performance.

At the BOA headquarters in Denver’s vibrant RiNo art district, engineers conducted off-snow testing in a state-of-the-art lab, as well as on-snow research at Eldora Mountain. “We use user feedback to refine the product configurations and system design, optimizing for a uniform wrap around the mid-foot for a better heel lock, which results in better pressure distribution, more confident turn initiation and higher force transfer from the boot to the ski,” explains Dickensheets. Through rigorous feedback and testing, BOA’s H+i1 system boasts a 13 percent reduction in peak pressures and pressure variation on top of the foot. But that’s not all the system achieved. Power transfer from boot to ski has increased by four-six percent in peak forces compared to your classic four-buckle boot. The final result? A boot you can’t truly appreciate until you slip your foot inside. Not tight, just right.